Why Vaccine Coolers Are Absolutely Essential: Protecting the Cold Chain

In the intricate and vital world of healthcare, few elements are as critical as the maintenance of the cold chain, particularly when it comes to vaccines. Vaccine coolers, often underestimated, stand as the unsung heroes in this process, acting as the crucial link that safeguards the potency and efficacy of life-saving immunizations from the point of manufacture to the moment of administration. Without reliable and meticulously maintained vaccine coolers, the integrity of these delicate biological products can be severely compromised, rendering them ineffective and potentially jeopardizing public health initiatives on a global scale. This comprehensive guide delves deep into the multifaceted world of vaccine coolers, exploring their diverse types, the indispensable features they must possess, and the stringent best practices that govern their use. Our aim is to provide an exhaustive understanding of why these specialized cooling units are not merely storage devices, but rather integral components of a robust healthcare infrastructure.

The sensitivity of vaccines to temperature fluctuations cannot be overstated. Exposure to temperatures outside the recommended range, even for brief periods, can lead to irreversible damage, diminishing their ability to elicit the intended immune response. This not only wastes valuable resources but, more importantly, leaves individuals vulnerable to preventable diseases. Therefore, investing in high-quality vaccine coolers and adhering to rigorous temperature monitoring protocols are not just best practices – they are ethical imperatives in the delivery of healthcare. This article will navigate the complexities of selecting the right vaccine cooler for specific needs, understanding the nuances of temperature control technology, and implementing strategies for optimal storage and transportation, ensuring that every dose administered is as potent and effective as intended.

Exploring the Diverse Landscape of Vaccine Coolers: Finding the Right Solution for Every Need

The term “vaccine cooler” encompasses a broad spectrum of devices, each designed to meet specific requirements for storage capacity, portability, and temperature control. Understanding the different types of vaccine coolers is crucial for healthcare providers and logistics professionals to make informed decisions that align with their operational needs and the specific demands of the vaccines they handle. From stationary refrigerators designed for long-term storage in clinics and pharmacies to portable units engineered for outreach programs and transportation, the variety of vaccine coolers ensures that there is a suitable solution for every stage of the vaccine delivery process.

-

Pharmaceutical-Grade Refrigerators: The Gold Standard for Stationary Storage

These specialized refrigerators are engineered with precise temperature control and monitoring capabilities, often featuring redundant systems to prevent temperature excursions. They typically have forced-air circulation to ensure uniform temperature distribution throughout the storage compartment, minimizing the risk of hot or cold spots. Features such as digital temperature displays with alarms, data logging capabilities, and secure locking mechanisms are standard in pharmaceutical-grade refrigerators, making them the cornerstone of vaccine storage in healthcare facilities.

-

Portable Vaccine Coolers: Ensuring Integrity on the Move

When vaccines need to be transported, whether for outreach clinics, home visits, or during emergency response situations, portable vaccine coolers become indispensable. These units range from insulated containers with ice packs or coolant packs (passive cooling) to actively powered coolers that maintain a consistent temperature via battery or external power sources. The key considerations for portable vaccine coolers include their ability to maintain the required temperature range for the duration of transport, their durability, ease of handling, and the reliability of their cooling mechanism.

-

Ultra-Low Temperature (ULT) Freezers: For Specialized Vaccine Storage

Certain vaccines, particularly some of the newer mRNA vaccines, require storage at ultra-low temperatures, often ranging from -80°C to -60°C. ULT freezers are specialized units designed to achieve and maintain these extreme temperature conditions. They employ sophisticated refrigeration systems and robust insulation to ensure the long-term stability of these highly sensitive vaccines. While not strictly “coolers” in the traditional sense, they are a critical component of the cold chain for specific vaccine types.

-

Benchtop Refrigerators: Compact Solutions for Limited Spaces

For smaller clinics or areas with limited space, benchtop refrigerators offer a compact yet reliable solution for vaccine storage. While smaller in capacity, pharmaceutical-grade benchtop models still provide the essential temperature control and monitoring features necessary to maintain vaccine efficacy.

The selection of the appropriate type of vaccine cooler depends on a multitude of factors, including the volume of vaccines to be stored, the frequency and duration of transportation, the specific temperature requirements of the vaccines, and the available infrastructure. A thorough assessment of these factors is essential to ensure the integrity of the vaccine supply chain.

Essential Features to Look for in a High-Quality Vaccine Cooler: Prioritizing Performance and Reliability

Investing in a vaccine cooler is a significant decision that directly impacts the quality of healthcare delivery. Therefore, it is paramount to consider several key features that distinguish high-quality units and ensure reliable performance. These features are designed to maintain the precise temperature environment required for vaccine storage, provide alerts in case of deviations, and offer the durability needed for long-term use.

-

Precise Temperature Control: Maintaining the Optimal Range

The ability to maintain a consistent temperature within the narrow recommended range (typically between 2°C and 8°C for refrigerated vaccines) is the most critical feature of a vaccine cooler. Look for units with accurate and responsive thermostats, as well as efficient cooling systems that minimize temperature fluctuations.

-

Forced-Air Circulation: Ensuring Uniform Temperature Distribution

For larger refrigerators, forced-air circulation systems are essential to prevent temperature stratification and ensure that all vaccines within the unit are stored at the correct temperature. This feature helps to eliminate hot and cold spots, providing a uniform environment throughout the storage space.

-

Digital Temperature Display and Monitoring: Real-Time Information and Alerts

A clear digital temperature display allows for easy monitoring of the internal temperature. High-quality vaccine coolers often include continuous temperature monitoring systems with audible and visual alarms that activate if the temperature deviates outside the acceptable range. Some advanced units also offer remote monitoring capabilities.

-

Data Logging Capabilities: Maintaining a Temperature History

The ability to automatically log temperature data is crucial for regulatory compliance and for identifying any potential temperature excursions that may have occurred. This data can be invaluable for quality control and for demonstrating adherence to cold chain protocols.

-

Secure Locking Mechanisms: Preventing Unauthorized Access

To safeguard valuable and sensitive vaccine supplies, vaccine coolers should be equipped with secure locking mechanisms to prevent unauthorized access and potential tampering.

-

Robust Construction and Insulation: Ensuring Durability and Efficiency

High-quality vaccine coolers are built with durable materials and effective insulation to ensure longevity and energy efficiency. Proper insulation helps to maintain the internal temperature and reduces the workload on the cooling system.

-

Compliance with Regulatory Standards: Meeting Healthcare Requirements

Ensure that the vaccine cooler you choose meets the relevant regulatory standards and guidelines for medical-grade refrigeration in your region. This often includes certifications and adherence to specific performance criteria.

Careful consideration of these features will help ensure that your investment in a vaccine cooler provides reliable and effective temperature control, safeguarding the integrity of your valuable vaccine supplies.

Implementing Best Practices for Vaccine Cooler Storage and Maintenance: Upholding the Cold Chain

Simply having a high-quality vaccine cooler is not enough to guarantee the integrity of vaccines. Adhering to strict best practices for storage, handling, and maintenance is equally crucial. These practices minimize the risk of temperature excursions and ensure the long-term reliability of the cooling equipment.

-

Proper Placement and Installation: Optimizing Performance

Ensure that the vaccine cooler is placed in a well-ventilated area, away from direct sunlight and heat sources. Allow adequate space around the unit for proper air circulation. Follow the manufacturer’s instructions for installation and leveling.

-

Temperature Monitoring and Documentation: Vigilance is Key

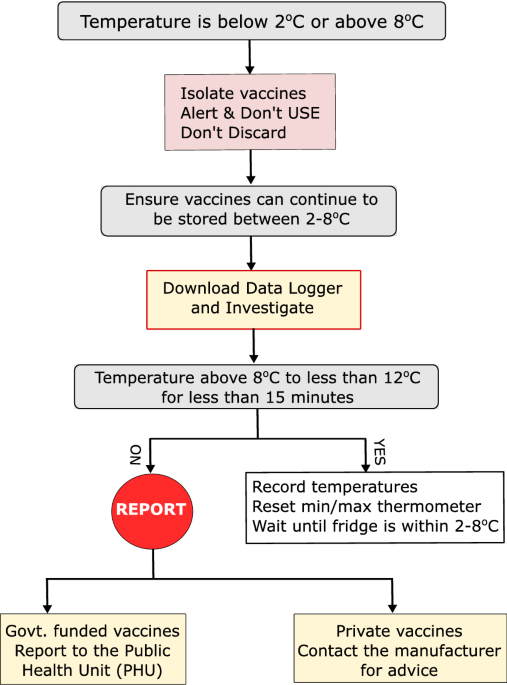

Implement a rigorous temperature monitoring schedule, checking and recording the internal temperature at least twice daily. Maintain detailed logs of temperature readings and any actions taken in response to temperature excursions. Utilize calibrated thermometers for accurate readings.

-

Organizing Vaccine Storage: Promoting Air Circulation

Arrange vaccines within the cooler to allow for proper air circulation. Avoid overcrowding shelves and ensure that there is space between items. Do not store food or other non-medical items in the vaccine cooler.

-

Regular Maintenance and Cleaning: Ensuring Longevity

Establish a routine maintenance schedule that includes regular cleaning of the interior and exterior of the vaccine cooler. Check and clean door seals to ensure a tight closure. Defrost manual-defrost freezers regularly to prevent ice buildup, which can affect temperature uniformity.

-

Emergency Preparedness: Planning for Power Outages

Develop a comprehensive plan for managing vaccine storage in the event of a power outage. This may include having access to backup power sources or utilizing insulated containers with coolant packs to maintain the required temperature temporarily. Have readily available temperature monitoring devices that do not rely on electricity.

-

Staff Training: Educating for Compliance

Ensure that all staff members who handle vaccines and vaccine coolers are thoroughly trained on proper storage procedures, temperature monitoring protocols, and emergency procedures. Regular refresher training is essential to reinforce best practices.

By diligently implementing these best practices, healthcare providers can maximize the effectiveness of their vaccine coolers and ensure that every administered dose maintains its full potency, contributing to better patient outcomes and stronger public health.

The Indispensable Role of Vaccine Coolers in Public Health

In conclusion, vaccine coolers are far more than mere refrigeration units; they are critical guardians of public health. Their ability to maintain the delicate temperature requirements of vaccines ensures that these life-saving medications remain effective from production to administration. Understanding the different types of vaccine coolers, recognizing the essential features that guarantee their performance, and diligently adhering to best practices for storage and maintenance are all vital components of a robust cold chain. By prioritizing the selection of high-quality vaccine coolers and implementing stringent protocols, healthcare professionals can safeguard the potency of vaccines, protect vulnerable populations, and contribute to a healthier future for all. The investment in reliable vaccine coolers and the commitment to their proper use are not just logistical considerations; they are fundamental responsibilities in the delivery of quality healthcare and the preservation of public trust in immunization programs.

© 2025 All Rights Reserved. [Your Organization Name/Website]