In a world where maintaining precise temperatures is paramount for everything from preserving perishable goods to facilitating critical industrial processes, refrigeration units stand as indispensable cornerstones. This comprehensive guide delves deep into the multifaceted realm of refrigeration units, exploring their diverse types, underlying principles, crucial features, energy efficiency considerations, essential maintenance practices, and the critical factors to consider when selecting the ideal unit for your unique requirements. Prepare to gain an unparalleled understanding of these vital systems that underpin modern life.

Understanding the Fundamental Principles of Refrigeration

At its core, refrigeration is the process of removing heat from an enclosed space or substance and transferring it elsewhere, resulting in a lower temperature. This seemingly simple concept relies on intricate thermodynamic principles, most commonly the vapor-compression cycle. This cycle involves a refrigerant, a specialized fluid that circulates through a closed system, undergoing phase changes from liquid to gas and back again. The key components facilitating this process include the compressor, which increases the pressure and temperature of the refrigerant gas; the condenser, where the high-pressure gas releases heat and condenses into a liquid; the expansion valve, which reduces the pressure and temperature of the liquid refrigerant; and the evaporator, where the low-pressure liquid absorbs heat from the surroundings, causing it to vaporize. Understanding these fundamental components and their interplay is crucial for appreciating the functionality and efficiency of various refrigeration units.

A Comprehensive Overview of Different Types of Refrigeration Units

The landscape of refrigeration units is vast and varied, tailored to meet a wide spectrum of needs, from household kitchens to large-scale industrial complexes. Here’s an in-depth look at some of the most common types:

-

Domestic Refrigeration Units

These are the familiar refrigerators and freezers found in homes. They range in size and configuration, including top-freezer, bottom-freezer, side-by-side, and French-door models. Key features often include adjustable shelving, humidity-controlled drawers, and frost-free operation. Energy efficiency is a significant consideration for domestic units, with energy-star certified models offering substantial long-term savings.

-

Commercial Refrigeration Units

Designed for businesses in the food service, retail, and hospitality industries, commercial refrigeration units are built for durability, high capacity, and consistent performance under demanding conditions. This category encompasses a wide array of equipment, including:

- Walk-in coolers and freezers: Large, insulated rooms that provide substantial storage space for perishable goods.

- Reach-in refrigerators and freezers: Upright units with glass or solid doors, offering easy access to stored items.

- Display cases: Refrigerated units designed to showcase products while maintaining optimal temperatures, commonly found in supermarkets and convenience stores.

- Under-counter refrigerators and freezers: Space-saving units ideal for kitchens and bars with limited room.

- Blast chillers and freezers: Rapidly cool or freeze food items to ensure safety and preserve quality.

Industrial Refrigeration Units

Industrial refrigeration units are heavy-duty systems employed in large-scale applications such as food processing plants, chemical manufacturing facilities, and cold storage warehouses. These systems often utilize different refrigerants and more complex configurations to achieve and maintain very low temperatures or handle large thermal loads. Reliability and energy efficiency are paramount in these demanding environments.

Transport Refrigeration Units

Maintaining temperature control during the transportation of perishable goods is crucial. Transport refrigeration units, mounted on trucks, trailers, and shipping containers, ensure that products like food and pharmaceuticals remain within specified temperature ranges throughout their journey. These units must be robust and reliable, capable of withstanding varying environmental conditions and vibrations.

Specialty Refrigeration Units

This category includes units designed for specific applications, such as laboratory refrigerators and freezers for storing biological samples and chemicals, medical-grade refrigerators for vaccines and pharmaceuticals, and wine refrigerators for maintaining the ideal temperature and humidity for wine storage.

Key Features and Technologies in Modern Refrigeration Units

Advancements in technology have led to significant improvements in the performance, efficiency, and convenience of refrigeration units. Some key features and technologies to consider include:

- Energy Efficiency: Look for units with high Energy Efficiency Ratio (EER) or Coefficient of Performance (COP) ratings. Features like variable speed compressors, improved insulation, and smart controls contribute to reduced energy consumption and lower operating costs.

- Temperature Control Systems: Precise and reliable temperature control is essential for preserving the quality and safety of stored items. Digital controls, multiple temperature zones, and advanced sensors ensure consistent temperatures throughout the unit.

- Frost Management: Frost buildup can significantly reduce the efficiency of a refrigeration unit. Features like automatic defrost cycles (frost-free) eliminate the need for manual defrosting.

- Airflow and Humidity Control: Proper air circulation and humidity levels are crucial for preventing spoilage and maintaining the freshness of food. Features like multi-airflow systems and humidity-controlled drawers help optimize these conditions.

- Smart Features: Increasingly, refrigeration units are incorporating smart technologies such as Wi-Fi connectivity, remote monitoring, and diagnostic capabilities. These features can enhance convenience and allow for proactive maintenance.

- Refrigerant Type: The type of refrigerant used has a significant impact on the environmental footprint and energy efficiency of the unit. Newer refrigerants are being developed with lower Global Warming Potential (GWP).

- Noise Levels: The noise produced by a refrigeration unit can be a consideration, especially in residential or quiet commercial environments. Look for units with low noise ratings.

- Build Quality and Durability: Investing in a refrigeration unit with high-quality components and robust construction ensures long-term reliability and reduces the likelihood of costly repairs.

The Critical Importance of Energy Efficiency in Refrigeration

Energy efficiency is no longer just a desirable feature but a critical consideration when selecting a refrigeration unit. Inefficient units can consume significant amounts of electricity, leading to high energy bills and a larger carbon footprint. When evaluating refrigeration units, pay close attention to energy efficiency ratings and certifications. Investing in an energy-efficient model not only saves money in the long run but also contributes to environmental sustainability. Factors influencing energy efficiency include the type of compressor, the quality of insulation, the effectiveness of the door seals, and the presence of features like variable speed drives and smart controls. Understanding and prioritizing energy efficiency is a hallmark of a discerning buyer.

Essential Maintenance Practices for Longevity and Optimal Performance

Regular maintenance is crucial for ensuring the longevity, efficiency, and reliable performance of your refrigeration unit. Neglecting maintenance can lead to reduced cooling capacity, increased energy consumption, and costly breakdowns. Key maintenance practices include:

- Regular Cleaning: Clean the interior and exterior of the unit regularly to prevent the buildup of dirt, dust, and food debris. Pay attention to door seals, ensuring they are clean and in good condition to maintain a tight seal.

- Coil Cleaning: The condenser coils, typically located at the back or bottom of the unit, dissipate heat. Dust and dirt accumulation on these coils can significantly reduce efficiency. Clean the coils regularly using a brush or vacuum cleaner.

- Checking and Maintaining Door Seals: Damaged or dirty door seals allow cold air to escape, forcing the unit to work harder. Inspect the seals regularly and clean or replace them if necessary.

- Proper Loading and Organization: Avoid overpacking the refrigeration unit, as this can impede airflow. Organize items in a way that allows for proper circulation of cold air.

- Regular Inspections: Periodically inspect the unit for any signs of leaks, unusual noises, or temperature fluctuations. Address any issues promptly to prevent more significant problems.

- Professional Servicing: Schedule regular professional servicing to ensure that all components are functioning correctly and to identify any potential issues before they escalate.

Factors to Consider When Selecting the Ideal Refrigeration Unit

Choosing the right refrigeration unit requires careful consideration of your specific needs and requirements. Key factors to evaluate include:

- Capacity and Size: Determine the amount of storage space you need based on the volume of items you will be refrigerating. Consider the physical dimensions of the available space.

- Type of Unit: Select the appropriate type of refrigeration unit based on its intended application (domestic, commercial, industrial, transport, or specialty).

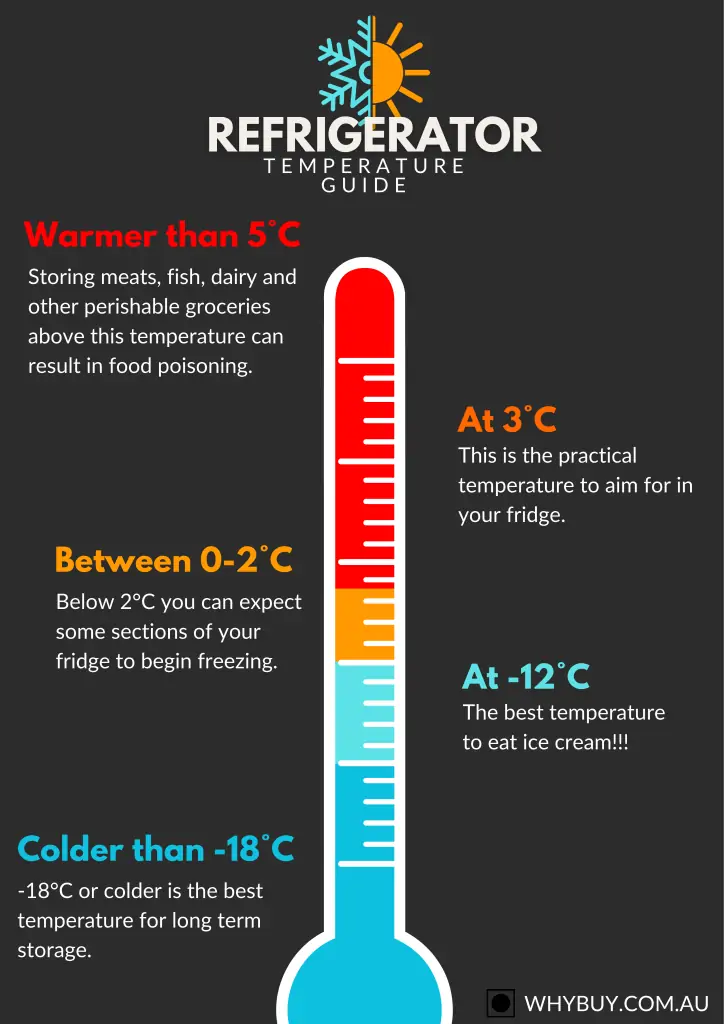

- Temperature Requirements: Ensure that the unit can maintain the specific temperature range required for the items you will be storing.

- Energy Efficiency: Prioritize units with high energy efficiency ratings to minimize operating costs and environmental impact.

- Budget: Consider both the initial purchase price and the long-term operating costs, including energy consumption and potential maintenance expenses.

- Features and Technologies: Evaluate the features and technologies that are important for your needs, such as temperature control systems, frost management, and smart features.

- Reliability and Durability: Research the brand reputation and read reviews to assess the reliability and durability of the unit.

- Maintenance Requirements: Consider the ease of maintenance and the availability of service and support.

- Noise Level: If noise is a concern, check the noise rating of the unit.

- Aesthetics: For consumer-facing applications, the appearance of the refrigeration unit may also be a factor.

By carefully considering these factors, you can make an informed decision and select a refrigeration unit that meets your specific needs and provides reliable and efficient temperature control for years to come.

© 2025 All Rights Reserved. [Your Company Name/Website]