Understanding Thermo King Alarm Codes

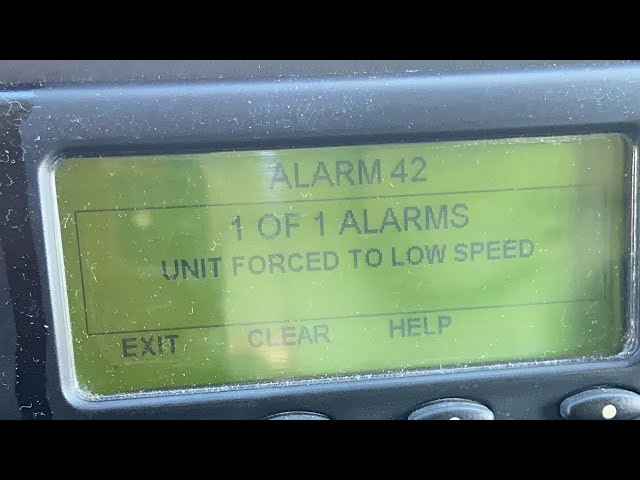

Thermo King refrigeration units are essential for maintaining temperature-sensitive cargo. However, like any complex system, they can encounter issues. When problems arise, the unit displays alarm codes, providing valuable clues about the nature of the malfunction. Understanding these codes is crucial for quick and efficient troubleshooting.

These codes are designed to help technicians and operators identify specific problems, ranging from simple sensor issues to complex mechanical failures. By recognizing and interpreting these codes, you can minimize downtime and ensure your cargo remains at the correct temperature.

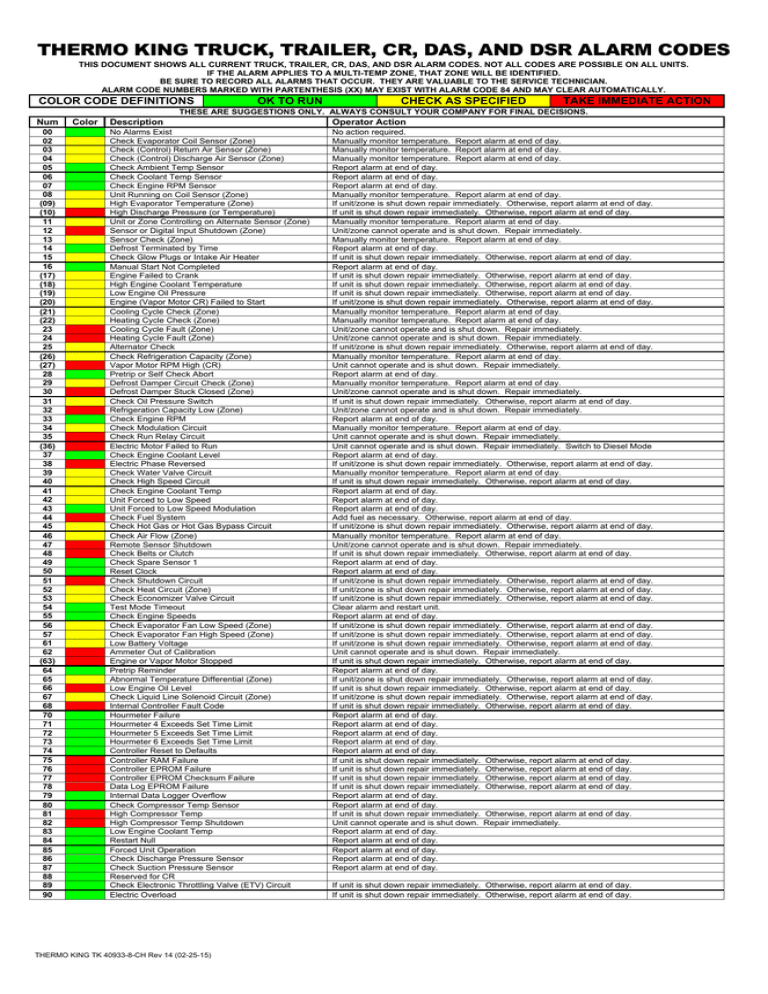

Common Thermo King Alarm Codes and Their Meanings

Here’s a breakdown of some of the most common Thermo King alarm codes you might encounter:

-

Alarm Code 11: High Discharge Pressure – This indicates that the pressure in the discharge line is exceeding the safe operating limit. Possible causes include a blocked condenser coil, a faulty fan, or overcharging.

-

Alarm Code 12: Low Suction Pressure – This suggests that the pressure in the suction line is too low. Potential causes include a refrigerant leak, a restricted filter drier, or a malfunctioning expansion valve.

-

Alarm Code 16: High Engine Coolant Temperature – This indicates that the engine coolant is overheating, potentially due to a faulty thermostat, a blocked radiator, or low coolant levels.

-

Alarm Code 31: Sensor Failure – this code indicates a sensor has failed. Often this code will need to be followed by another code, that specifies what sensor has failed.

-

Alarm Code 41: Defrost Termination Failure – this code means the defrost cycle did not end properly. This can be caused by a faulty sensor, or a problem with the defrost timer.

It’s important to consult your Thermo King unit’s manual for a complete list of alarm codes and their specific meanings, as codes can vary depending on the model.

Troubleshooting Tips for Thermo King Alarms

When you encounter a Thermo King alarm code, follow these troubleshooting steps:

-

Record the Alarm Code: Note the exact code displayed on the unit’s control panel. This will be essential for diagnosing the problem.

-

Consult the Manual: Refer to your Thermo King unit’s manual for the specific meaning of the alarm code and recommended troubleshooting procedures.

-

Check Basic Components: Inspect easily accessible components, such as filters, belts, and fluid levels, for any obvious signs of damage or wear.

-

Reset the Unit: In some cases, resetting the unit may clear the alarm code. However, if the problem persists, further investigation is required.

-

Seek Professional Assistance: If you’re unable to resolve the issue, contact a certified Thermo King technician for expert diagnosis and repair.

Preventive Maintenance for Thermo King Units

Regular preventive maintenance is key to avoiding alarm codes and ensuring the reliable operation of your Thermo King unit. Here are some essential maintenance tasks:

-

Regular Inspections: Conduct routine inspections to check for leaks, damage, and wear.

-

Filter Replacements: Replace air and fuel filters according to the manufacturer’s recommendations.

-

Fluid Checks: Monitor and maintain proper fluid levels, including engine oil, coolant, and refrigerant.

-

Belt Inspections: Check belts for tension and wear, and replace them as needed.

-

System Cleaning: Regularly clean condenser and evaporator coils to ensure efficient heat transfer.

Importance of Quick Response to Thermo King Alarms

Responding promptly to Thermo King alarm codes is crucial for maintaining the integrity of your cargo. Delays in addressing these issues can lead to temperature fluctuations, which can damage or spoil temperature-sensitive goods.

By understanding and addressing alarm codes quickly, you can minimize downtime, reduce repair costs, and ensure the safe and efficient transport of your cargo.

© [Your Company Name] – All Rights Reserved