Thermo King units are the backbone of refrigerated transport, ensuring that temperature-sensitive goods arrive in perfect condition. But like any complex machinery, they can encounter issues. That’s where Thermo King codes come into play. Understanding these codes is crucial for quick and effective troubleshooting, minimizing downtime and preventing costly cargo spoilage. This guide will walk you through the essential aspects of Thermo King diagnostics, helping you decipher those cryptic messages and keep your units running smoothly.

Understanding Thermo King Diagnostic Systems

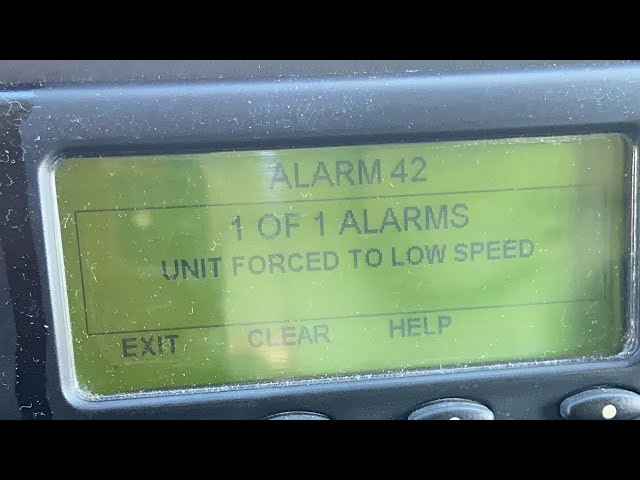

Thermo King units utilize sophisticated electronic control systems that monitor various parameters, from temperature and pressure to engine performance. When a problem arises, the system generates a code, displayed on the unit’s control panel. These codes provide valuable information about the nature of the issue, allowing technicians to pinpoint the source of the problem and take appropriate action.

Key Components of the Diagnostic System

- Microprocessor Controller: The brain of the system, responsible for monitoring and controlling all aspects of the unit’s operation.

- Sensors: Various sensors throughout the unit provide real-time data on temperature, pressure, and other critical parameters.

- Display Panel: The interface that displays error codes and other diagnostic information.

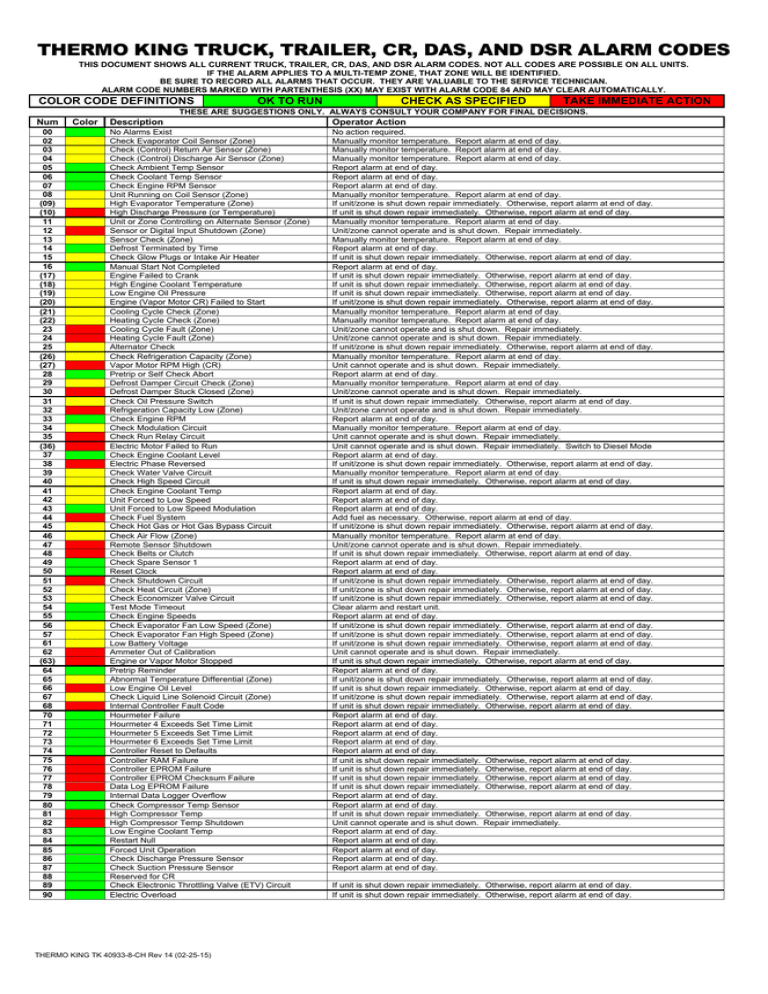

Common Thermo King Code Categories

Thermo King codes can be broadly categorized based on the system they relate to:

- Engine Codes: These codes indicate problems with the engine, such as low oil pressure, high coolant temperature, or fuel system issues.

- Refrigeration Codes: These codes relate to issues with the refrigeration system, such as temperature sensor failures, compressor problems, or refrigerant leaks.

- Electrical Codes: These codes indicate problems with the electrical system, such as wiring faults, fuse failures, or control module issues.

- Sensor Codes: these codes are related to the various sensors used by the thermo king unit.

Deciphering Thermo King Codes: A Step-by-Step Approach

When you encounter a Thermo King code, follow these steps to troubleshoot the issue:

- Record the Code: Note down the exact code displayed on the control panel.

- Consult the Manual: Refer to the Thermo King operator’s manual for a detailed explanation of the code.

- Identify the System: Determine which system the code relates to (engine, refrigeration, electrical).

- Check Basic Components: Inspect the relevant components for obvious signs of damage or malfunction.

- Use Diagnostic Tools: If necessary, use diagnostic tools to further investigate the issue.

- Contact a Technician: If you are unable to resolve the issue, contact a qualified Thermo King technician.

Example Thermo King Codes and Their Meanings

Here are a few examples of common Thermo King codes and their potential meanings:

- Code 128: Engine oil pressure low.

- Code 132: Coolant temperature high.

- Code 096: Fuel filter restriction.

- Code 029: Discharge air temperature sensor fault.

- Code 041: Return air temperature sensor fault.

- Code 011: Compressor discharge pressure high.

Important Note: This is not an exhaustive list. Always consult the Thermo King operator’s manual for a complete list of codes and their meanings.

Preventive Maintenance: Avoiding Thermo King Codes

Regular preventive maintenance is essential for minimizing the occurrence of Thermo King codes. This includes:

- Regular Inspections: Conduct regular inspections of the unit, checking for leaks, damage, and wear.

- Fluid Checks: Regularly check and maintain fluid levels, including engine oil, coolant, and refrigerant.

- Filter Replacements: Replace air filters, fuel filters, and oil filters according to the manufacturer’s recommendations.

- System Calibrations: Periodically calibrate sensors and other components to ensure accurate readings.

- Proper Cleaning: Keep the unit clean and free of debris.

Advanced Diagnostics and Tools

Modern Thermo King units often interface with advanced diagnostic tools. These tools can provide detailed information about the unit’s performance, including real-time data, historical data, and fault logs. Using these tools, technicians can quickly identify and resolve complex issues.

Thermo King’s TracKing: For example, Thermo King’s TracKing system allows for remote monitoring and diagnostics, providing valuable insights into the unit’s operation and enabling proactive maintenance.

Conclusion

Understanding Thermo King codes is vital for maintaining the efficiency and reliability of your refrigerated transport operations. By following the troubleshooting steps outlined in this guide and implementing a comprehensive preventive maintenance program, you can minimize downtime, prevent costly repairs, and ensure that your temperature-sensitive goods arrive in perfect condition. Remember, when in doubt, always consult the Thermo King operator’s manual or contact a qualified technician. By mastering these codes, you ensure that your Thermo King unit is in perfect working order.