Ensuring the potency and efficacy of vaccines is paramount to public health. A critical aspect of this is the meticulous and correct storage of vaccines, particularly within a refrigerator. Improper storage can lead to irreversible damage, rendering these life-saving biological products ineffective and potentially dangerous. This comprehensive guide delves deep into the nuances of vaccine storage in a refrigerator, providing actionable insights and best practices to guarantee the integrity of your valuable vaccine supply.

Understanding the Critical Importance of Proper Vaccine Refrigeration

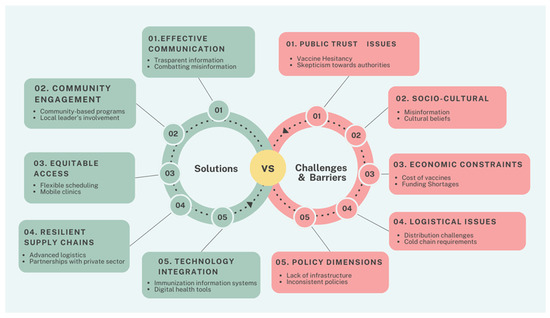

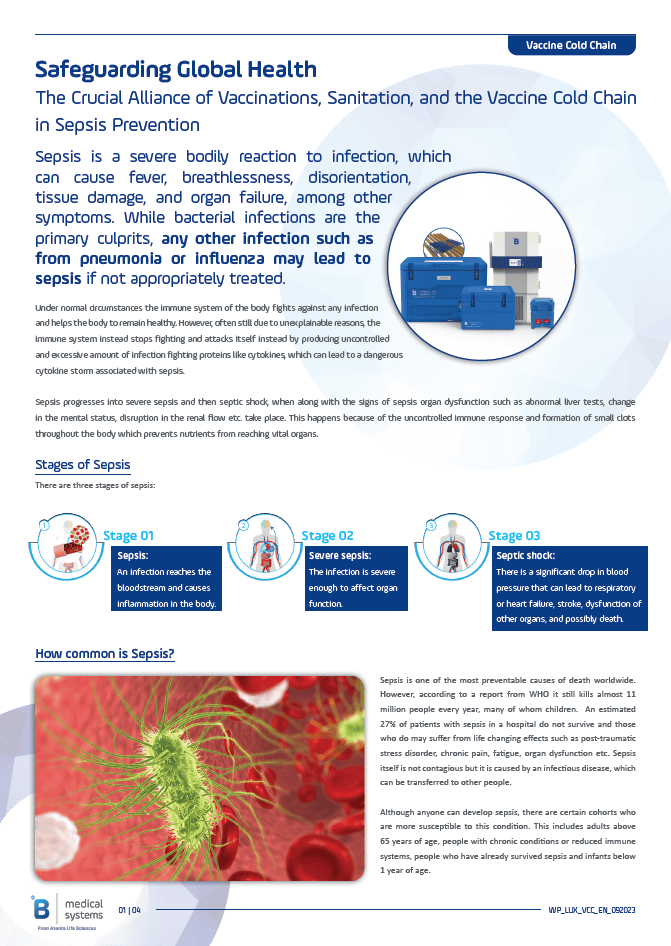

Vaccines are sensitive biological preparations that can be easily compromised by deviations in temperature. Exposure to temperatures outside the recommended range can lead to a significant reduction in their effectiveness, even if the change is not visually apparent. This can result in inadequate protection for individuals receiving the vaccine, undermining vaccination efforts and potentially leading to outbreaks of preventable diseases. Maintaining a strict cold chain – the system of maintaining optimal temperature conditions during the transport, storage, and handling of vaccines – is therefore non-negotiable. The refrigerator plays a pivotal role in this chain, acting as a crucial storage point.

Selecting the Right Refrigerator for Vaccine Storage: Key Considerations

Not all refrigerators are created equal when it comes to storing vaccines. A standard household refrigerator is generally not recommended due to inconsistent temperature fluctuations and the risk of freezing in certain areas. The ideal refrigerator for vaccine storage is a purpose-built pharmaceutical-grade refrigerator or a high-quality medical-grade refrigerator. These units are specifically designed with features that ensure consistent and uniform temperature control, often including:

- Forced-air circulation: This ensures even temperature distribution throughout the unit, minimizing hot and cold spots.

- Precise temperature control and monitoring systems: These refrigerators often have digital displays and alarms to alert users of any temperature excursions.

- Dedicated compartments or zones: Some models offer separate zones for different temperature requirements, although this is less common for standard refrigerated vaccines.

- Secure locking mechanisms: To prevent unauthorized access and potential tampering.

If a pharmaceutical-grade refrigerator is not immediately feasible, a high-quality domestic refrigerator with a separate freezer compartment (to avoid accidental freezing) may be used temporarily, provided stringent temperature monitoring and management protocols are in place. However, long-term reliance on such units is discouraged.

Optimal Temperature Range and Monitoring Procedures

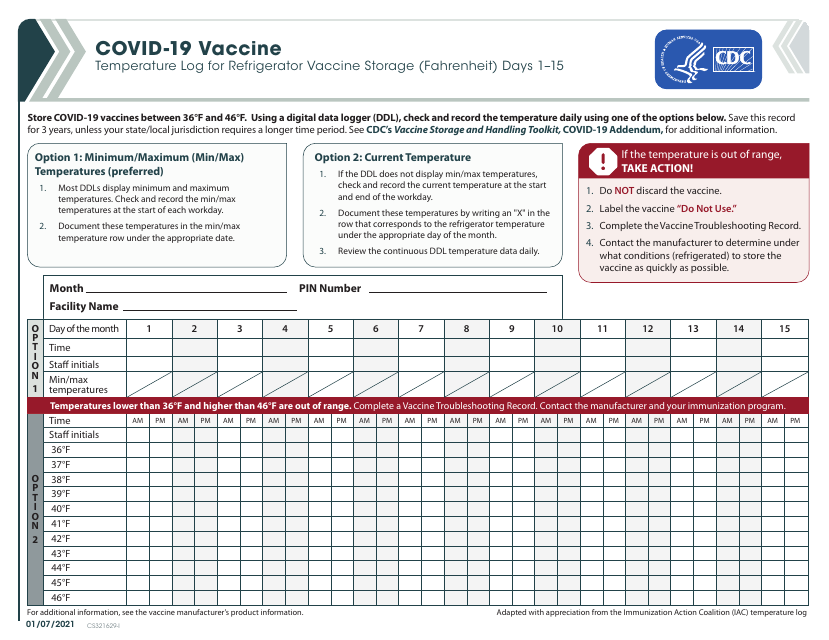

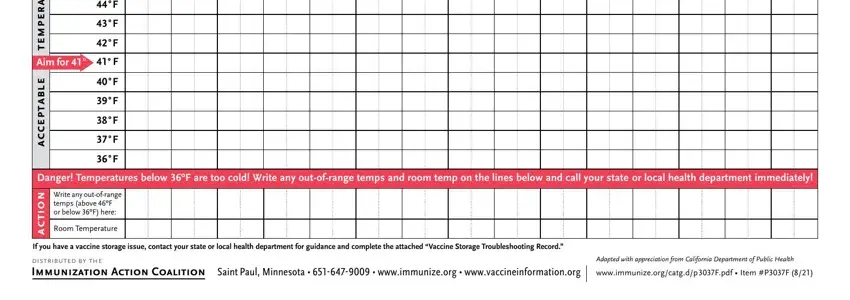

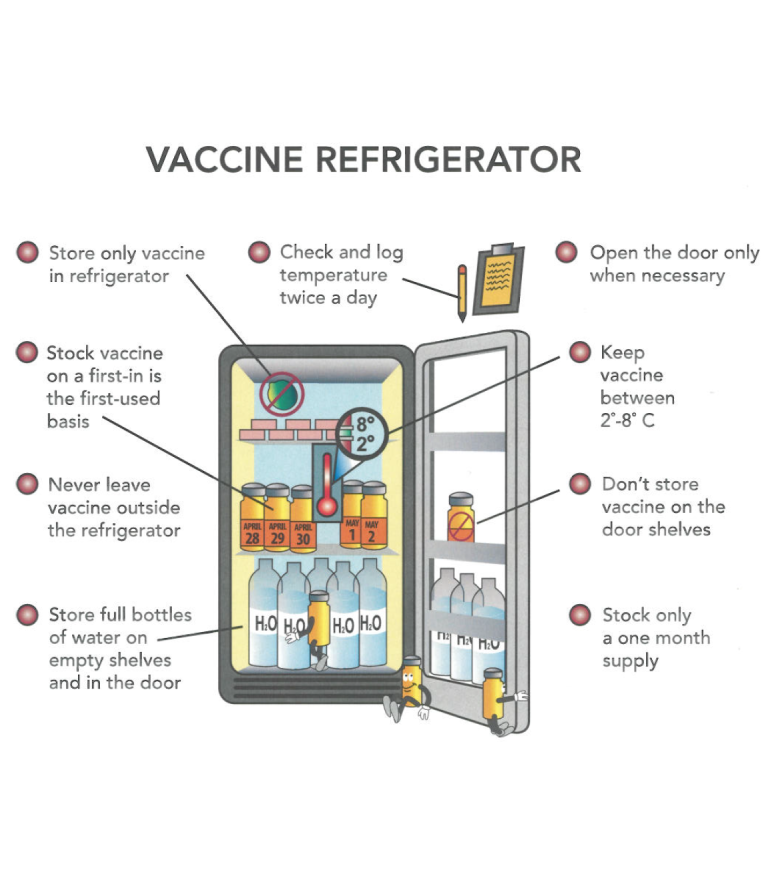

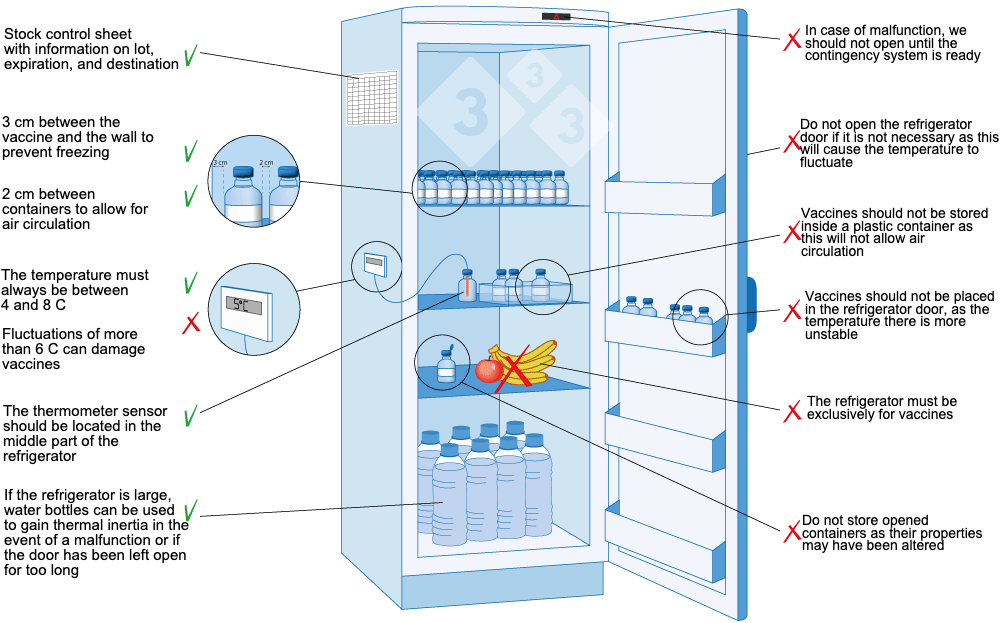

The generally recommended temperature range for storing most refrigerated vaccines is between 2°C and 8°C (36°F and 46°F). It is absolutely crucial to maintain this temperature range consistently. To ensure this, rigorous temperature monitoring is essential:

- Use calibrated thermometers: Employ digital data loggers or calibrated thermometers with a certificate of calibration. Avoid using alcohol or mercury thermometers, as they can be unreliable and pose safety risks.

- Place thermometers strategically: Position one thermometer in the warmest part of the refrigerator and another in the coldest part. This helps to identify any temperature variations within the unit.

- Monitor temperatures at least twice daily: Record the minimum and maximum temperatures each day, preferably at the beginning and end of the workday. Maintain a detailed log of these readings.

- Implement continuous temperature monitoring systems: Data loggers provide a continuous record of temperature fluctuations and can alert users to any excursions outside the acceptable range in real-time. This is the gold standard for temperature monitoring.

- Establish an action plan for temperature excursions: Clearly define the steps to be taken if the temperature falls outside the 2°C to 8°C range. This includes isolating the affected vaccines, contacting the relevant authorities or manufacturers for guidance, and documenting the event thoroughly.

Organizing Your Vaccine Refrigerator for Maximum Efficiency and Safety

Proper organization within the vaccine refrigerator is vital for maintaining consistent temperatures and preventing errors. Follow these best practices:

- Do not overcrowd the refrigerator: Allow for adequate air circulation around the vaccine packages to ensure uniform cooling.

- Store vaccines in their original packaging: This provides an extra layer of protection and helps with identification.

- Arrange vaccines logically: Organize vaccines alphabetically or by date of expiry, ensuring that the vaccine with the nearest expiration date is easily accessible.

- Avoid storing vaccines in the refrigerator door: The temperature in the door compartments tends to fluctuate more than in the main body of the refrigerator.

- Keep vaccines away from the cooling vents and the back walls: These areas can be too cold and pose a risk of freezing.

- Clearly label all vaccines: Ensure that each vaccine is clearly identified with its name, lot number, and expiration date.

- Do not store food, drinks, or other non-medical items in the vaccine refrigerator: This minimizes the risk of contamination and ensures that the refrigerator is dedicated solely to vaccine storage.

- Implement a system for inventory management: Regularly check and rotate your vaccine stock to prevent wastage due to expiration.

Essential Maintenance and Troubleshooting for Your Vaccine Refrigerator

Regular maintenance is crucial for the optimal performance and longevity of your vaccine refrigerator:

- Clean the refrigerator regularly: Follow the manufacturer’s instructions for cleaning. Promptly address any spills.

- Defrost the refrigerator if necessary: Excessive frost buildup can impair cooling efficiency. However, many pharmaceutical-grade refrigerators are frost-free.

- Check door seals regularly: Ensure that the door seals are intact and create a tight seal to maintain the internal temperature.

- Schedule regular professional maintenance: Have the refrigerator inspected and serviced by a qualified technician according to the manufacturer’s recommendations.

Troubleshooting common issues can also prevent significant problems:

- Temperature fluctuations: Investigate potential causes such as door left ajar, overcrowding, or a malfunctioning thermostat.

- Alarm activation: Respond immediately to any temperature alarms and take corrective action.

- Power outages: Have a contingency plan in place for power outages, including access to a backup generator or alternative storage options.

Responding to Temperature Excursions: A Critical Protocol

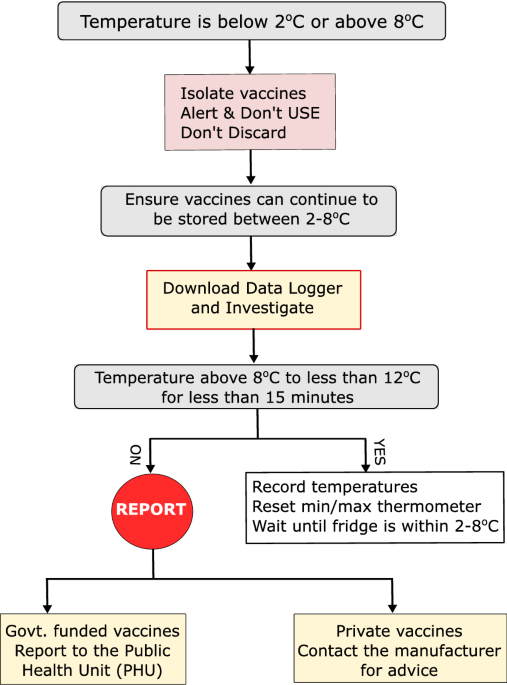

Despite diligent monitoring, temperature excursions outside the recommended range can occasionally occur. It is vital to have a well-defined protocol in place to address these situations effectively:

- Immediately identify and isolate the affected vaccines: Clearly label them as “Do Not Use” and store them separately.

- Document the temperature excursion thoroughly: Record the date, time, duration, and the minimum and maximum temperatures reached. Note any potential causes of the excursion.

- Contact the relevant authorities or vaccine manufacturers for guidance: They can provide specific advice on the viability of the affected vaccines based on the duration and extent of the temperature deviation. Do not discard or use the vaccines without their explicit guidance.

- Complete a detailed incident report: This report should include all relevant information about the excursion, the actions taken, and the outcome.

- Review and revise storage protocols: Analyze the cause of the temperature excursion and implement measures to prevent future occurrences.

The Future of Vaccine Storage Technology

The field of vaccine storage is constantly evolving, with advancements in technology aimed at improving efficiency and safety. These include more sophisticated temperature monitoring systems, smart refrigerators with automated alerts and reporting capabilities, and innovative packaging solutions designed to maintain optimal temperatures during transport and storage. Staying informed about these advancements can help optimize your vaccine storage practices in the long run.

Conclusion: Upholding the Integrity of Vaccines Through Diligent Refrigeration

The storage of vaccines in a refrigerator is not merely about keeping them cold; it is a critical process that directly impacts their efficacy and the health of the individuals who receive them. By understanding the principles of proper refrigeration, selecting the right equipment, implementing rigorous monitoring protocols, and adhering to best practices for organization and maintenance, healthcare providers can ensure the integrity of their vaccine supply. This commitment to excellence in vaccine storage is a cornerstone of effective immunization programs and a vital responsibility in safeguarding public health. By prioritizing these crucial steps, we contribute to a healthier and safer future for all.