Whether you’re a seasoned ice cream shop owner or a curious DIY enthusiast, understanding the inner workings of a Taylor ice cream machine is crucial. A detailed Taylor ice cream machine parts diagram serves as your roadmap to maintenance, troubleshooting, and even repairs. In this comprehensive guide, we’ll explore the key components, their functions, and how to interpret these vital diagrams.

Why Understanding Your Taylor Machine’s Parts Is Essential

Taylor machines are renowned for their reliability and efficiency. However, like any complex machinery, they require regular upkeep. Familiarity with the parts diagram allows you to:

- Identify and replace worn-out components promptly.

- Troubleshoot common issues without relying solely on technicians.

- Perform routine maintenance tasks effectively.

- Order the correct replacement parts with precision.

Key Components and Their Functions

Let’s delve into the core components you’ll typically find in a Taylor ice cream machine parts diagram:

1. Compressor

The compressor is the heart of the refrigeration system. It circulates refrigerant, which absorbs heat and cools the freezing cylinder. A properly functioning compressor is vital for consistent ice cream production.

2. Freezing Cylinder

The freezing cylinder is where the magic happens. The ice cream mix freezes against the cylinder’s inner walls, forming the creamy texture we all love. Regular cleaning and maintenance of this component are essential to prevent buildup and ensure optimal performance.

3. Beater Assembly

The beater assembly, including the dasher and blades, mixes and scrapes the frozen ice cream from the cylinder walls. This assembly is crucial for achieving the desired consistency and overrun. Inspecting and maintaining the beater assembly ensures smooth operation.

4. Valves and Seals

Valves and seals prevent leaks and maintain proper pressure within the machine. These small components play a significant role in the overall efficiency and reliability of the Taylor machine. Regularly checking and replacing worn seals can prevent costly breakdowns.

5. Control Panel and Electronics

The control panel and electronics regulate the machine’s functions, including temperature, mixing speed, and dispensing. Understanding the control panel’s layout and functions is essential for operating the machine correctly and troubleshooting issues.

6. Drive Motor

The drive motor powers the beater assembly and other moving parts. Ensuring the motor is properly lubricated and maintained is crucial for smooth operation and longevity.

7. Condenser

The Condenser is a heat exchanger. It releases the heat from the refrigerant to the surrounding air. Keeping the condenser clean is important for the machine’s efficiency.

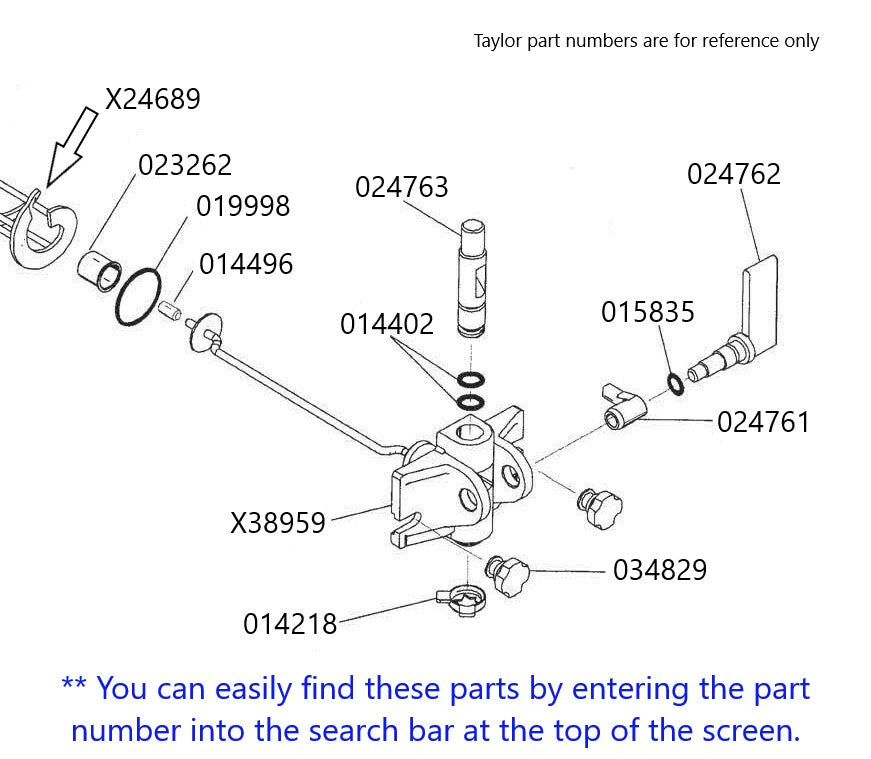

Visual Aids: Diagrams and Illustrations

A high-quality Taylor ice cream machine parts diagram should include clear illustrations and labels for each component. These visual aids are invaluable for understanding the machine’s assembly and identifying specific parts. Look for diagrams that:

- Are detailed and easy to read.

- Include part numbers for easy ordering.

- Show exploded views for complex assemblies.

You can often find these diagrams in the machine’s user manual or from authorized Taylor parts suppliers.

Maintenance Tips and Troubleshooting

Regular maintenance is key to keeping your Taylor ice cream machine in top condition. Here are a few essential tips:

- Clean the machine thoroughly after each use.

- Inspect and replace worn seals and gaskets.

- Lubricate moving parts as recommended by the manufacturer.

- Monitor refrigerant levels and compressor performance.

- Check and clean the condenser coils.

If you encounter any issues, consult your Taylor ice cream machine parts diagram and troubleshooting guide. Common problems include:

- Ice cream that is too soft or too hard.

- Leaks or drips.

- Unusual noises or vibrations.

- Control panel errors.

If you’re unsure about any repairs or maintenance tasks, it’s always best to consult a qualified technician.

Finding the Right Parts

When you need to replace a part, having the correct part number from the Taylor ice cream machine parts diagram is essential. Purchase parts from authorized Taylor suppliers to ensure compatibility and quality.

By understanding the components and their functions, you can keep your Taylor ice cream machine running smoothly and efficiently, ensuring delicious ice cream for years to come.