In the realm of appliance manufacturing, precision and efficiency are paramount. The refrigerator gasket welding machine stands as a testament to technological advancement, significantly streamlining the production of vital refrigerator components. This article delves into the intricacies of these machines, exploring their benefits, types, and the profound impact they have on the industry.

Understanding Refrigerator Gasket Welding Machines

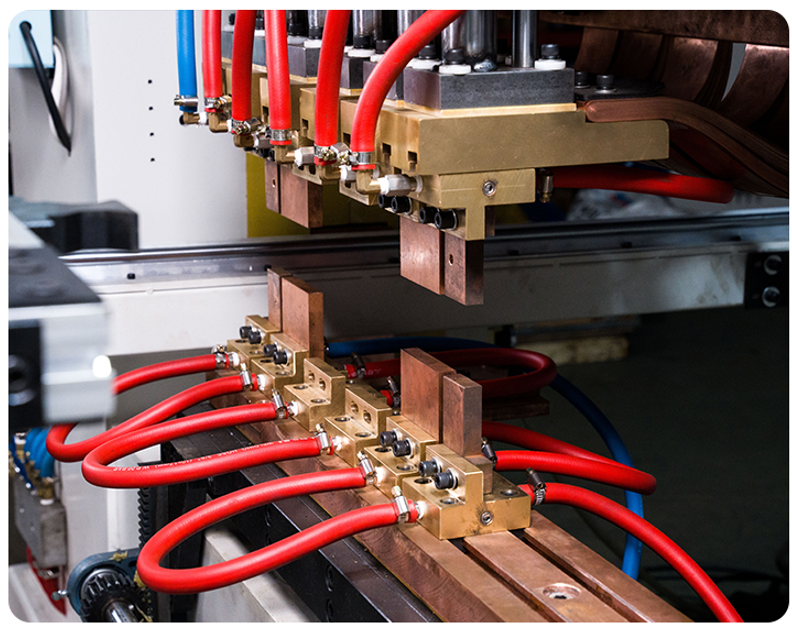

A refrigerator gasket welding machine is a specialized piece of equipment designed to join the thermoplastic materials that form refrigerator door gaskets. These gaskets are crucial for maintaining an airtight seal, preserving the freshness of food, and ensuring energy efficiency. Modern machines employ advanced welding techniques, such as high-frequency welding or hot air welding, to create durable and seamless bonds.

Key Benefits

- Enhanced Efficiency: Automated welding processes significantly reduce production time and labor costs.

- Superior Quality: Consistent and precise welds ensure a high-quality finished product.

- Reduced Material Waste: Optimized welding techniques minimize material usage and waste.

- Increased Durability: Strong and reliable welds extend the lifespan of refrigerator gaskets.

- Versatility: Machines can be adapted to handle various gasket sizes and designs.

Types of Welding Technologies

Several welding technologies are employed in refrigerator gasket welding machines, each offering unique advantages:

High-Frequency Welding

This method uses electromagnetic energy to heat and fuse thermoplastic materials. It’s known for its speed and precision, creating strong and seamless welds. High-frequency welding machines are widely used in high-volume production environments.

Hot Air Welding

Hot air welding involves heating the thermoplastic materials with a stream of hot air and then pressing them together. This method is versatile and suitable for various gasket materials and designs. It’s often used for smaller production runs or specialized applications.

Ultrasonic Welding

This method uses high-frequency ultrasonic acoustic vibrations to generate heat at the joint between two parts. It is very fast and efficient, and creates strong bonds. This is used in many industries, and is also found in some forms of refrigerator gasket welding machines.

The Impact on Manufacturing

The introduction of refrigerator gasket welding machines has revolutionized the appliance manufacturing industry. These machines have significantly improved production efficiency, reduced costs, and enhanced the quality of refrigerator gaskets. As technology continues to advance, we can expect even more sophisticated welding solutions that further optimize manufacturing processes.

Choosing the Right Machine

Selecting the right refrigerator gasket welding machine depends on several factors, including production volume, gasket material, and specific design requirements. Manufacturers should consider the machine’s features, performance, and reliability to ensure it meets their needs.

Future Trends

The future of refrigerator gasket welding machines is bright, with ongoing advancements in automation and robotics. Expect to see more integrated systems that combine welding with other manufacturing processes, such as cutting and assembly. Additionally, advancements in material science will lead to the development of new gasket materials that offer improved performance and durability.

In conclusion, the refrigerator gasket welding machine is a critical component in modern appliance manufacturing. Its ability to produce high-quality, durable gaskets efficiently makes it an indispensable tool for manufacturers seeking to stay competitive in the market. As technology continues to evolve, these machines will play an even more significant role in shaping the future of the industry.