Welcome to the most comprehensive resource on refrigeration systems. Whether you are an industry professional, a student of engineering, or simply curious about the technology that underpins our modern world, this guide will delve deep into the principles, advancements, and diverse applications of cooling solutions that shape our lives.

Understanding the Fundamentals of Refrigeration

At its core, refrigeration is the process of removing heat from an enclosed space or substance and transferring it elsewhere. This fundamental principle, rooted in the laws of thermodynamics, enables us to preserve food, maintain comfortable environments, and facilitate countless industrial processes. The journey of refrigeration has been one of continuous innovation, from early ice harvesting techniques to the sophisticated mechanical and chemical systems we rely on today.

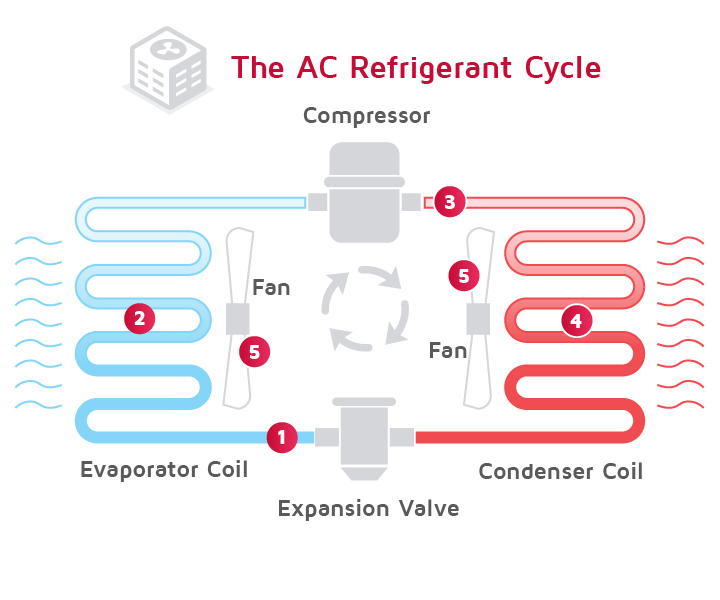

The basic refrigeration cycle involves four key components and processes:

- Evaporation: A low-pressure liquid refrigerant absorbs heat from its surroundings, causing it to vaporize. This is where the cooling effect occurs.

- Compression: The refrigerant vapor is compressed, increasing its temperature and pressure. This requires energy input, typically in the form of electricity.

- Condensation: The high-pressure, high-temperature refrigerant vapor releases heat to its surroundings (usually air or water) and condenses back into a liquid.

- Expansion: The high-pressure liquid refrigerant passes through an expansion valve or device, causing its pressure and temperature to drop significantly, ready to repeat the cycle in the evaporator.

Understanding these core principles is crucial to appreciating the complexity and ingenuity behind modern refrigeration systems.

Types of Refrigeration Systems: A Comprehensive Overview

The world of refrigeration encompasses a vast array of systems, each designed for specific needs and applications. Here, we explore some of the most prevalent types:

Vapor-Compression Refrigeration Systems

This is the most common type of refrigeration system, widely used in residential refrigerators, air conditioners, and large-scale industrial applications. It relies on the cycle described above, utilizing various refrigerants to facilitate heat transfer. Advancements in compressor technology, such as scroll and inverter compressors, have significantly improved the efficiency and performance of these systems.

Vapor-Absorption Refrigeration Systems

Unlike vapor-compression systems that use mechanical compressors, vapor-absorption systems utilize heat as their primary energy source. These systems typically employ a refrigerant (like ammonia or water) and an absorbent (like water or lithium bromide). They are often used in situations where waste heat is readily available or where electricity is scarce or expensive. While historically less efficient than vapor-compression systems, modern advancements are improving their performance and sustainability.

Evaporative Cooling Systems

Evaporative cooling, also known as swamp cooling, utilizes the principle of evaporative cooling, where the evaporation of water absorbs heat from the surrounding air, lowering its temperature. These systems are particularly effective in hot, dry climates and are commonly used for cooling large spaces like warehouses and industrial facilities. While not technically a closed-loop refrigeration system, it provides a significant cooling effect through a natural process.

Thermoelectric Refrigeration Systems (Peltier Coolers)

Thermoelectric coolers utilize the Peltier effect, where a temperature difference is created by passing an electric current through two dissimilar semiconductor materials. These systems are compact, have no moving parts, and offer precise temperature control. They are commonly used in small-scale applications like portable coolers, scientific instruments, and electronic component cooling.

Magnetic Refrigeration Systems

This emerging technology utilizes the magnetocaloric effect, where certain magnetic materials heat up when exposed to a magnetic field and cool down when the field is removed. Magnetic refrigeration promises higher energy efficiency and the elimination of harmful refrigerants, making it a potentially game-changing technology for the future.

Cryogenic Refrigeration Systems

Cryogenics deals with the production and maintenance of very low temperatures (typically below -150°C or -238°F). Cryogenic refrigeration systems employ specialized techniques and refrigerants like liquid nitrogen and liquid helium to achieve these extreme temperatures, essential for applications in scientific research, medical imaging (MRI), and the transportation of liquefied gases.

The Crucial Role of Refrigerants in Refrigeration Systems

Refrigerants are the working fluids that absorb and transport heat within a refrigeration system. Their properties, such as boiling point, latent heat of vaporization, and chemical stability, are critical to the system’s performance and efficiency. Historically, a variety of substances have been used as refrigerants, including chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). However, due to their detrimental impact on the ozone layer and their contribution to global warming, these substances are being phased out under international agreements like the Montreal Protocol.

The focus of modern refrigerant development is on environmentally friendly alternatives, such as:

- Hydrofluorocarbons (HFCs): While ozone-safe, some HFCs have high global warming potentials (GWPs), leading to ongoing efforts to transition to lower-GWP alternatives.

- Hydrofluoroolefins (HFOs): These synthetic refrigerants have very low GWPs and are considered promising replacements for many HFCs.

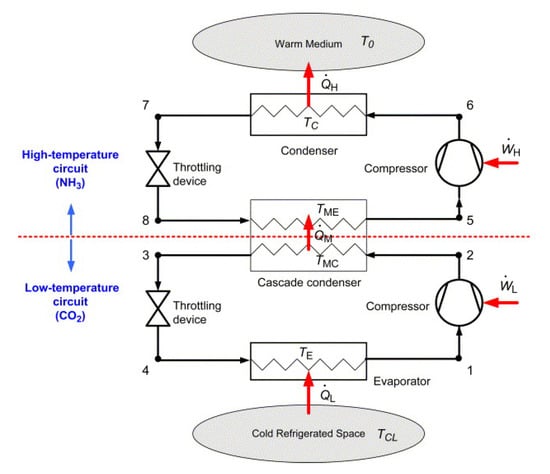

- Natural Refrigerants: Substances like ammonia (R717), carbon dioxide (R744), and hydrocarbons (like propane and isobutane) offer excellent thermodynamic properties and low or zero GWPs. Their use is increasing in various applications, often requiring specific safety considerations.

The selection of the appropriate refrigerant is a critical decision in the design and operation of any refrigeration system, balancing performance, efficiency, safety, and environmental impact.

Diverse Applications of Refrigeration Systems Across Industries

Refrigeration systems are indispensable across a wide spectrum of industries, playing a vital role in processes and ensuring the quality and safety of countless products and services. Some key applications include:

- Food Preservation and Storage: From household refrigerators to large-scale cold storage facilities, refrigeration is essential for preserving food quality, extending shelf life, and preventing spoilage, ensuring a stable and safe food supply chain.

- Air Conditioning and Comfort Cooling: Refrigeration systems are the backbone of air conditioning in residential, commercial, and industrial buildings, providing comfortable and healthy indoor environments.

- Industrial Processes: Many industrial processes rely on precise temperature control achieved through refrigeration, including chemical manufacturing, pharmaceuticals, plastics production, and metalworking.

- Transportation and Logistics (Cold Chain): Refrigerated transport, including trucks, trains, and ships, is crucial for maintaining the temperature of perishable goods during transit, ensuring their quality upon arrival.

- Healthcare and Medical Applications: Refrigeration is vital for storing vaccines, medications, blood products, and biological samples. Cryogenic refrigeration is used in medical imaging (MRI) and cryosurgery.

- Data Centers and Electronics Cooling: Maintaining optimal operating temperatures for sensitive electronic equipment in data centers and other high-tech environments is essential for reliability and performance, often achieved through sophisticated refrigeration and cooling systems.

- Superconducting Technologies: Cryogenic refrigeration is indispensable for maintaining the extremely low temperatures required for superconductivity in various applications, including scientific research and advanced transportation.

The continued development and refinement of refrigeration technologies are crucial for addressing the growing global demand for cooling while minimizing environmental impact.

Energy Efficiency and Sustainability in Refrigeration

Given the significant energy consumption associated with refrigeration systems globally, improving energy efficiency and promoting sustainability are paramount. Innovations and best practices in this area include:

- High-Efficiency Compressors: Advanced compressor designs, such as inverter-driven compressors, can significantly reduce energy consumption by adjusting their speed to match cooling demand.

- Improved Heat Exchangers: Optimizing the design and materials of evaporators and condensers enhances heat transfer efficiency, reducing energy waste.

- Advanced Insulation Materials: Better insulation minimizes heat leakage into refrigerated spaces, reducing the workload on the refrigeration system.

- Smart Controls and Automation: Implementing intelligent control systems allows for precise temperature management and optimization of system operation based on real-time conditions.

- Leak Detection and Prevention: Minimizing refrigerant leaks not only reduces environmental impact but also improves system efficiency and reduces operating costs.

- Natural Refrigerants: Transitioning to refrigerants with low or zero GWPs and high energy efficiency contributes significantly to environmental sustainability.

- Waste Heat Recovery: Utilizing waste heat generated by refrigeration systems for other purposes, such as water heating, can improve overall energy efficiency.

The future of refrigeration hinges on the continued development and adoption of energy-efficient and environmentally responsible technologies and practices.

The Future of Refrigeration Systems: Trends and Innovations

The field of refrigeration is constantly evolving, driven by the need for greater efficiency, reduced environmental impact, and new applications. Some key trends and innovations shaping the future include:

- Smart and Connected Systems: Integrating IoT (Internet of Things) technologies into refrigeration systems enables remote monitoring, predictive maintenance, and optimized performance.

- Advanced Materials: Research into new materials with enhanced thermal conductivity and other beneficial properties will lead to more efficient and compact systems.

- Sustainable Cooling Solutions: Continued development and adoption of natural refrigerants and alternative cooling technologies like magnetic refrigeration and thermoelectric cooling will drive sustainability.

- Micro-Refrigeration and Miniaturization: The demand for compact and efficient cooling solutions for electronics, medical devices, and other specialized applications is driving innovation in micro-refrigeration technologies.

- Integration with Renewable Energy: Combining refrigeration systems with renewable energy sources like solar power can further reduce their environmental footprint.

- Improved System Design and Optimization: Advanced modeling and simulation tools are enabling the design of more efficient and reliable refrigeration systems tailored to specific needs.

The ongoing pursuit of innovation in refrigeration is essential for addressing global challenges related to food security, climate change, and technological advancement.

© 2025 All Rights Reserved. Your Company/Website Name.