In the intricate landscape of modern industrial and commercial operations, the ability to precisely control temperature is not merely a convenience; it is a fundamental requirement for efficiency, quality, and safety. At the heart of many critical processes lies the refrigerated chiller, a sophisticated piece of equipment engineered to provide consistent and reliable cooling for a vast array of applications. This comprehensive guide delves deep into the world of refrigerated chillers, exploring their core principles, diverse types, crucial selection criteria, essential maintenance practices, and the exciting future of this vital technology. Prepare to unlock the secrets of optimized temperature control and discover how the right refrigerated chiller can elevate your operations to new heights.

Understanding the Core Principles of Refrigerated Chillers

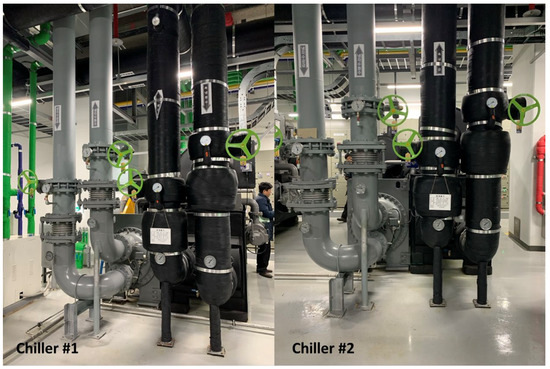

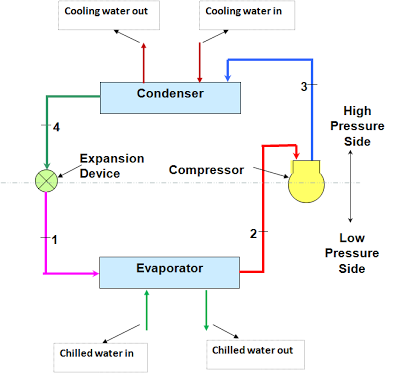

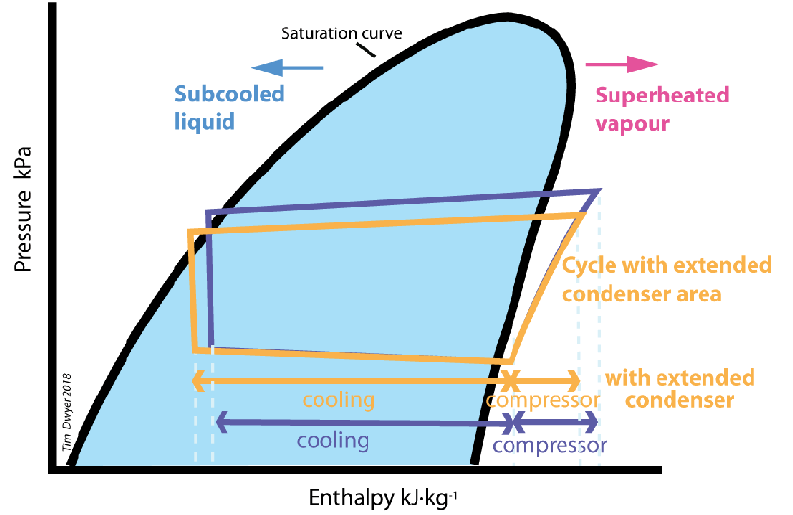

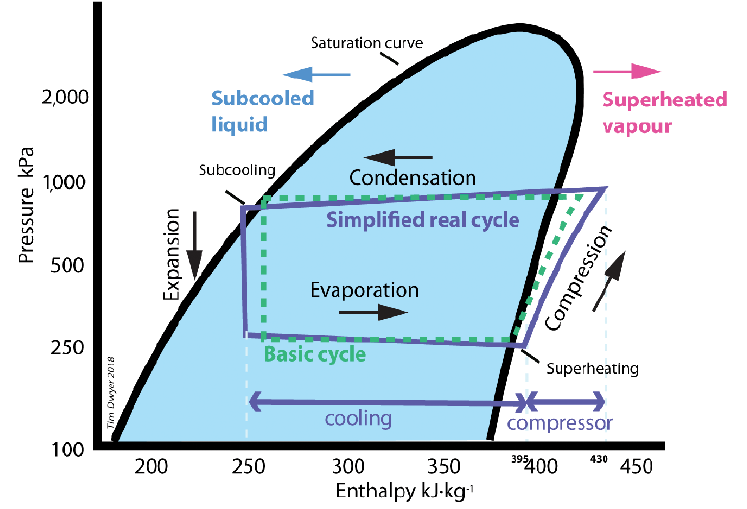

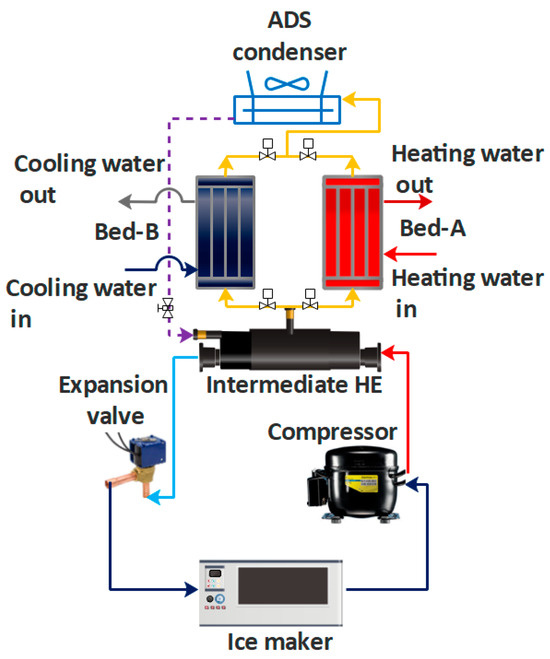

At its essence, a refrigerated chiller operates on the fundamental principles of thermodynamics and refrigeration. It functions by circulating a refrigerant through a closed-loop system, absorbing heat from a fluid (typically water or a water-glycol mixture) and then rejecting that heat to a different environment. This continuous cycle allows for the precise and consistent cooling of the process fluid, which is then used to regulate the temperature of equipment, machinery, or spaces. The key components involved in this process include the compressor, responsible for increasing the pressure and temperature of the refrigerant; the condenser, where the high-pressure refrigerant releases heat; the expansion valve, which reduces the pressure and temperature of the refrigerant; and the evaporator, where the cold refrigerant absorbs heat from the process fluid. Understanding this cycle is crucial for appreciating the capabilities and limitations of different refrigerated chiller designs.

- The Refrigeration Cycle: A detailed breakdown of evaporation, compression, condensation, and expansion.

- Heat Transfer Mechanisms: Exploring how heat is absorbed and rejected within the chiller system.

- Types of Refrigerants: An overview of common refrigerants and their environmental considerations.

Exploring the Diverse Types of Refrigerated Chillers and Their Applications

The world of refrigerated chillers is far from monolithic. A wide array of designs and configurations exists, each tailored to meet the specific demands of different applications. Understanding these distinctions is paramount when selecting the optimal chiller for your needs.

Air-Cooled vs. Water-Cooled Chillers

One of the primary distinctions lies in the method of heat rejection. Air-cooled chillers utilize ambient air to dissipate heat through finned coils and fans. They are generally easier to install and maintain, making them a popular choice for smaller to medium-sized applications where water availability or quality is a concern. Conversely, water-cooled chillers transfer heat to a separate water loop, which then carries the heat to a cooling tower or other heat rejection source. While often requiring more complex installation, water-cooled chillers typically offer higher energy efficiency and are better suited for larger capacity applications.

Other Key Chiller Types

- Scroll Chillers: Known for their energy efficiency and quiet operation, ideal for HVAC and light industrial applications.

- Screw Chillers: Robust and reliable, offering high cooling capacities for large industrial processes.

- Centrifugal Chillers: Capable of handling very large cooling loads, commonly found in large commercial buildings and industrial plants.

- Absorption Chillers: Utilize a heat source instead of a compressor, offering potential energy savings in specific scenarios.

- Portable Chillers: Compact and mobile units designed for temporary or localized cooling needs.

Diverse Applications Across Industries

Refrigerated chillers play a critical role in a vast spectrum of industries, including:

- Manufacturing: Cooling industrial machinery, injection molding equipment, welding systems, and more to prevent overheating and ensure consistent product quality.

- Food and Beverage Processing: Maintaining precise temperatures for food preservation, fermentation, and cooling processes, ensuring safety and extending shelf life.

- Pharmaceuticals: Controlling temperatures in research, development, and manufacturing processes, crucial for drug stability and efficacy.

- Plastics Industry: Cooling molds in injection molding and blow molding processes to accelerate production cycles and improve product finish.

- Laser Technology: Providing stable cooling for sensitive laser equipment, ensuring optimal performance and longevity.

- Medical Imaging (MRI, CT Scanners): Dissipating heat generated by powerful magnets and electronic components, ensuring accurate imaging and patient safety.

- HVAC (Heating, Ventilation, and Air Conditioning): Providing chilled water for air conditioning systems in commercial and institutional buildings.

- Data Centers: Maintaining optimal operating temperatures for sensitive electronic equipment, preventing overheating and ensuring system reliability.

Key Considerations When Selecting a Refrigerated Chiller

Choosing the right refrigerated chiller is a critical decision that can significantly impact operational efficiency and costs. Several key factors must be carefully considered to ensure the selected unit meets your specific requirements.

- Cooling Capacity: Determining the precise amount of heat that needs to be removed, typically measured in tons or kilowatts. Accurate load calculations are essential to avoid undersizing or oversizing the chiller.

- Temperature Requirements: Specifying the desired supply and return temperatures of the process fluid, as well as the required temperature stability.

- Flow Rate: Calculating the necessary flow rate of the process fluid to ensure adequate heat transfer.

- Energy Efficiency: Evaluating the chiller’s energy efficiency ratio (EER) or coefficient of performance (COP) to minimize operating costs and environmental impact. Consider features like variable speed drives and economizers.

- Footprint and Space Constraints: Assessing the available space for installation and ensuring the chosen chiller fits within the designated area.

- Noise Levels: Considering noise sensitivity in the operating environment and selecting a chiller with appropriate noise reduction features.

- Maintenance Requirements: Evaluating the ease of maintenance and the availability of spare parts. Regular maintenance is crucial for optimal performance and longevity.

- Budget: Balancing the initial purchase cost with long-term operating and maintenance expenses.

- Environmental Factors: Considering ambient temperature variations and humidity levels, which can affect chiller performance.

- Control Systems: Evaluating the sophistication of the chiller’s control system and its ability to integrate with existing building management systems.

Essential Maintenance Practices for Optimal Refrigerated Chiller Performance and Longevity

Like any complex mechanical system, refrigerated chillers require regular and diligent maintenance to ensure optimal performance, energy efficiency, and a long operational lifespan. Neglecting maintenance can lead to decreased cooling capacity, increased energy consumption, costly repairs, and premature system failure. Implementing a proactive maintenance program is a wise investment.

- Regular Inspections: Conducting routine visual inspections to identify any leaks, corrosion, or unusual noises.

- Cleaning Coils: Keeping condenser and evaporator coils clean to ensure efficient heat transfer. Dirty coils can significantly reduce performance.

- Checking Refrigerant Levels: Monitoring refrigerant levels and addressing any leaks promptly. Low refrigerant can severely impact cooling capacity.

- Water Treatment: Implementing proper water treatment for water-cooled chillers to prevent scale buildup, corrosion, and biological growth in the water loops.

- Filter Replacement: Regularly replacing air filters in air-cooled chillers to maintain proper airflow.

- Lubrication: Ensuring proper lubrication of moving parts, such as compressor motors and bearings, according to manufacturer recommendations.

- Calibration of Controls: Periodically calibrating temperature sensors and control systems to ensure accurate and efficient operation.

- Professional Servicing: Scheduling regular maintenance by qualified HVAC technicians for comprehensive inspections and servicing.

- Log Keeping: Maintaining detailed records of maintenance activities, repairs, and performance data to identify trends and potential issues.

The Future of Refrigerated Chiller Technology: Innovation and Sustainability

The field of refrigerated chiller technology is constantly evolving, driven by the increasing demand for greater energy efficiency, reduced environmental impact, and enhanced performance. Several exciting trends are shaping the future of these critical cooling systems.

- Energy Efficiency Advancements: Ongoing research and development are focused on improving the energy efficiency of chillers through advanced compressor designs, heat exchanger technologies, and intelligent control systems.

- Sustainable Refrigerants: The industry is transitioning towards more environmentally friendly refrigerants with lower global warming potential (GWP) to comply with evolving regulations and reduce the carbon footprint.

- Smart Controls and IoT Integration: The integration of sophisticated sensors, microprocessors, and the Internet of Things (IoT) is enabling real-time monitoring, remote diagnostics, predictive maintenance, and optimized energy management.

- Variable Speed Technology: The increasing adoption of variable speed drives (VSDs) for compressors and pumps allows chillers to precisely match cooling capacity to the actual load, resulting in significant energy savings.

- Hybrid Systems: Combining different cooling technologies, such as chillers with free cooling systems, to leverage ambient conditions and reduce energy consumption.

- Microchannel Heat Exchangers: These compact and efficient heat exchangers offer improved heat transfer performance and reduced refrigerant charge.

Conclusion: Investing in the Right Refrigerated Chiller for a Sustainable and Efficient Future

The refrigerated chiller stands as a cornerstone of countless industrial and commercial processes, providing the essential temperature control necessary for optimal performance, quality, and safety. By understanding the fundamental principles, exploring the diverse types and applications, carefully considering selection criteria, implementing proactive maintenance practices, and staying abreast of future technological advancements, businesses can make informed decisions that lead to significant operational benefits. Investing in the right refrigerated chiller is not just an expenditure; it is a strategic investment in efficiency, sustainability, and the long-term success of your operations. Embrace the power of precision cooling and unlock the full potential of your processes with a meticulously chosen and well-maintained refrigerated chiller.