In the demanding landscape of modern industry, where precision and preservation are paramount, industrial refrigerators and freezers stand as indispensable cornerstones. Far beyond their domestic counterparts, these robust and sophisticated units are engineered to maintain critical temperature environments across a vast spectrum of applications. From safeguarding perishable goods in sprawling food processing plants to preserving vital pharmaceutical compounds in research laboratories, the reliability and efficiency of industrial refrigeration directly impact operational success, regulatory compliance, and ultimately, the bottom line. This comprehensive guide delves deep into the intricacies of industrial refrigerators and freezers, exploring their diverse types, crucial features, energy optimization strategies, essential maintenance protocols, and the critical factors to consider when selecting the ideal unit for your specific needs.

Understanding the Diverse Applications of Industrial Refrigeration

Industrial refrigerators and freezers serve a multitude of critical functions across various sectors. Their ability to maintain precise temperature control is essential for:

- Food and Beverage Industry: Preserving raw materials, work-in-progress goods, and finished products, ensuring food safety and extending shelf life in processing plants, storage facilities, and distribution centers. This includes everything from massive walk-in coolers for produce to high-capacity blast freezers for rapid chilling.

- Pharmaceutical and Healthcare: Storing temperature-sensitive medications, vaccines, biological samples, and reagents under strictly controlled conditions, vital for efficacy and safety. Specialized laboratory freezers and pharmaceutical refrigerators are designed with stringent temperature uniformity and monitoring capabilities.

- Chemical and Manufacturing: Maintaining specific temperatures for chemical reactions, material storage, and quality control processes. Certain industrial processes require ultra-low temperatures achievable with specialized cryogenic freezers.

- Research and Development: Providing controlled environments for scientific experiments, sample preservation, and long-term storage of valuable research materials. Ultra-low temperature freezers are crucial for preserving biological samples for extended periods.

- Agriculture and Horticulture: Post-harvest cooling and storage of fruits, vegetables, and other agricultural products to extend freshness and reduce spoilage, often utilizing large-scale cold storage warehouses.

The specific demands of each application necessitate a wide array of industrial refrigerator and freezer designs, each engineered with unique features and capabilities.

Exploring the Key Types of Industrial Refrigerators and Freezers

The world of industrial refrigeration encompasses a diverse range of equipment tailored to specific volume, temperature, and operational requirements. Some of the most common types include:

- Walk-in Coolers and Freezers: Large, customizable rooms designed for bulk storage, offering ample space for personnel to access and organize goods. They are widely used in supermarkets, restaurants, and food processing facilities.

- Reach-in Refrigerators and Freezers: Upright units with doors, offering convenient access to stored items. Available in various sizes and configurations, they are common in commercial kitchens and laboratories.

- Blast Freezers: Designed for rapidly freezing products, minimizing ice crystal formation and preserving product quality. Crucial in the food processing industry for maintaining texture and flavor.

- Spiral Freezers: Continuous freezing systems ideal for high-volume production lines, offering efficient and consistent freezing of food products.

- Tunnel Freezers: Another type of continuous freezer, often used for freezing individually quick-frozen (IQF) products.

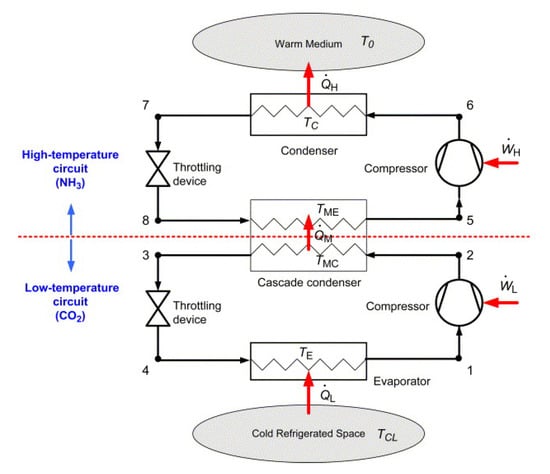

- Ultra-Low Temperature (ULT) Freezers: Capable of reaching extremely low temperatures (typically -80°C or lower), essential for preserving biological samples, pharmaceuticals, and certain chemical compounds.

- Display Refrigerators and Freezers: Designed to showcase products while maintaining optimal storage temperatures, commonly found in retail environments.

- Refrigerated Warehouses: Large-scale facilities providing controlled temperature storage for vast quantities of goods.

- Modular Cold Rooms: Customizable and scalable cold storage solutions that can be adapted to specific space and temperature requirements.

Understanding the specific operational needs is crucial in selecting the appropriate type of industrial refrigerator or freezer.

Essential Features and Technologies in Industrial Refrigeration

Modern industrial refrigerators and freezers are equipped with advanced features and technologies designed for optimal performance, efficiency, and reliability. Key aspects to consider include:

- Robust Construction: Built with durable materials like stainless steel to withstand demanding industrial environments and ensure longevity.

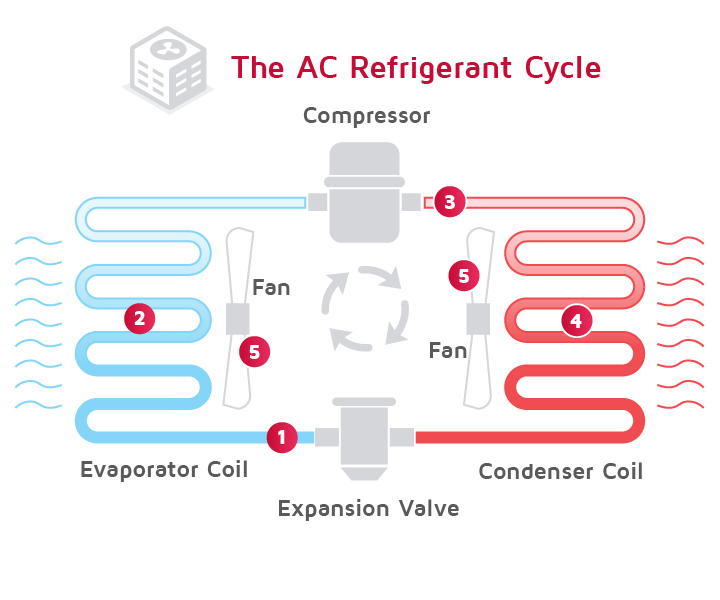

- Powerful Cooling Systems: Utilizing high-capacity compressors and efficient refrigerants to achieve and maintain precise temperature control even under heavy use.

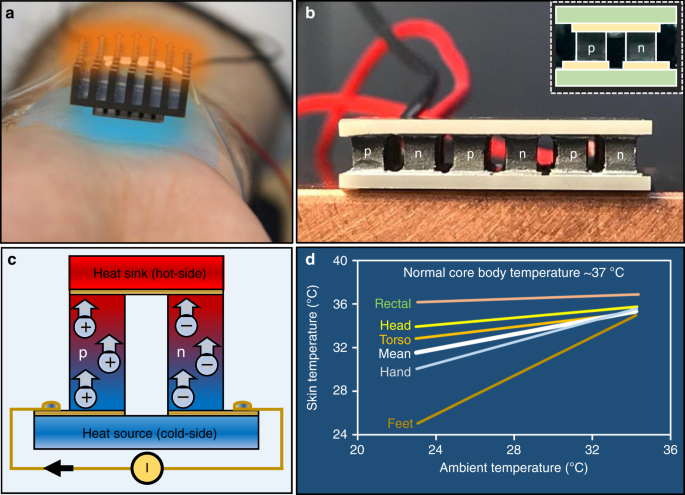

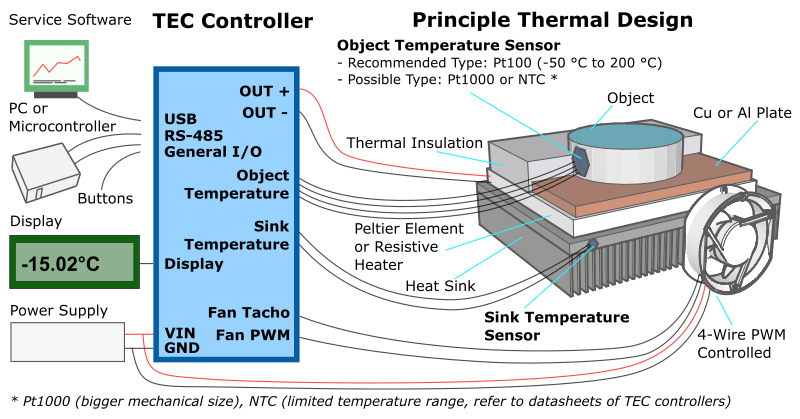

- Precise Temperature Control and Monitoring: Advanced digital controllers and sensors ensure accurate temperature maintenance and often include data logging capabilities for compliance and quality assurance.

- Effective Insulation: High-quality insulation materials minimize heat transfer, reducing energy consumption and maintaining consistent internal temperatures.

- Efficient Air Circulation: Strategically designed airflow systems ensure uniform temperature distribution throughout the unit, preventing hot spots and ensuring consistent product quality.

- Defrost Systems: Automatic defrost cycles prevent ice buildup, which can impair efficiency and reduce storage capacity. Various defrost methods are employed, including electric, hot gas, and air defrost.

- Door Seals and Closures: Tight-sealing doors and reliable closure mechanisms prevent cold air leakage, contributing to energy efficiency.

- Lighting: Energy-efficient internal lighting improves visibility and facilitates easy access to stored items.

- Safety Features: Including alarm systems for temperature deviations, door ajar warnings, and pressure relief valves.

The integration of smart technologies, such as remote monitoring and predictive maintenance capabilities, is becoming increasingly prevalent in modern industrial refrigeration systems.

Optimizing Energy Efficiency in Industrial Refrigeration Systems

Given the significant energy consumption associated with industrial refrigerators and freezers, optimizing energy efficiency is crucial for reducing operational costs and minimizing environmental impact. Key strategies include:

- Selecting Energy-Efficient Models: Investing in units with high Energy Efficiency Ratios (EER) or Coefficient of Performance (COP). Look for certifications and energy star ratings where applicable.

- Proper Insulation: Ensuring adequate and well-maintained insulation to minimize heat gain. Regularly inspect and repair any insulation damage.

- Effective Door Seals: Regularly inspecting and replacing worn or damaged door seals to prevent cold air leaks. Implementing air curtains or strip curtains in high-traffic areas can also help.

- Optimized Defrost Cycles: Implementing demand-defrost systems that initiate defrost cycles only when necessary, rather than on a fixed schedule.

- Efficient Condenser Coil Maintenance: Regularly cleaning condenser coils to ensure proper heat exchange. Dirty coils can significantly reduce efficiency.

- Proper Loading and Organization: Avoiding overpacking and ensuring proper airflow around stored items.

- Temperature Monitoring and Control: Implementing precise temperature control systems and regularly monitoring temperatures to avoid unnecessary cooling.

- Utilizing Natural Refrigerants: Considering units that utilize environmentally friendly refrigerants with low Global Warming Potential (GWP).

- Heat Recovery Systems: Exploring opportunities to recover waste heat generated by the refrigeration system for other applications, such as water heating.

Implementing a comprehensive energy management plan for your industrial refrigeration systems can lead to substantial long-term cost savings.

The Importance of Regular Maintenance for Industrial Refrigerators and Freezers

Consistent and thorough maintenance is paramount for ensuring the reliable operation, longevity, and efficiency of industrial refrigerators and freezers. Neglecting maintenance can lead to performance degradation, increased energy consumption, costly repairs, and even equipment failure. Essential maintenance practices include:

- Regular Cleaning: Cleaning both the interior and exterior of the units, including condenser coils, evaporator fans, and drainage systems.

- Inspection of Door Seals and Hinges: Regularly checking for damage or wear and tear and replacing components as needed.

- Monitoring Refrigerant Levels: Ensuring proper refrigerant charge and promptly addressing any leaks.

- Checking Electrical Connections: Inspecting wiring and connections for any signs of damage or corrosion.

- Testing Safety Features: Regularly verifying the functionality of alarms and safety mechanisms.

- Lubrication of Moving Parts: Lubricating fan motors and other moving components as recommended by the manufacturer.

- Calibration of Temperature Controls: Periodically calibrating temperature sensors and controllers to ensure accuracy.

- Professional Servicing: Scheduling regular maintenance checks with qualified refrigeration technicians to identify and address potential issues before they escalate.

Implementing a proactive maintenance schedule is a critical investment in the long-term performance and reliability of your industrial refrigeration equipment.

Key Considerations When Selecting Industrial Refrigerators and Freezers

Choosing the right industrial refrigerator or freezer for your specific needs requires careful consideration of several critical factors:

- Storage Capacity Requirements: Determine the volume of goods that need to be stored and select a unit with adequate internal space.

- Temperature Requirements: Identify the specific temperature range required for the products being stored. Different applications necessitate different temperature capabilities.

- Space Availability: Assess the available floor space and any dimensional constraints. Consider both the internal and external dimensions of the unit.

- Energy Efficiency: Evaluate the energy consumption of different models and choose an energy-efficient option to minimize operating costs.

- Budget: Consider both the initial purchase cost and the long-term operating and maintenance expenses.

- Durability and Reliability: Select units built with high-quality materials and a proven track record of reliability in industrial environments.

- Specific Features and Functionality: Identify any specific features required for your application, such as rapid freezing capabilities, precise temperature control, or remote monitoring.

- Compliance and Regulations: Ensure that the chosen unit meets all relevant industry standards and regulations.

- Manufacturer Reputation and Support: Choose a reputable manufacturer that offers reliable customer support, technical assistance, and readily available spare parts.

- Future Needs: Consider potential future growth and whether the chosen unit can accommodate increased storage requirements. Modular solutions may be advantageous in such cases.

A thorough assessment of these factors will ensure that you select the industrial refrigerator or freezer that best meets your operational requirements and provides long-term value.

The Future of Industrial Refrigeration: Innovation and Sustainability

The field of industrial refrigeration is continuously evolving, driven by advancements in technology and a growing emphasis on sustainability. Future trends include:

- Increased Use of Natural Refrigerants: Transitioning towards refrigerants with lower GWP, such as ammonia (R717), carbon dioxide (R744), and propane (R290), to reduce environmental impact.

- Smart Refrigeration Systems: Integration of IoT (Internet of Things) technologies for remote monitoring, predictive maintenance, and energy optimization.

- Improved Energy Efficiency Technologies: Development of more efficient compressors, heat exchangers, and insulation materials.

- Advanced Control Systems: Implementation of sophisticated algorithms and controls for precise temperature management and energy savings.

- Sustainable Design and Manufacturing: Focus on using environmentally friendly materials and manufacturing processes.

Staying informed about these advancements will be crucial for businesses looking to invest in cutting-edge and sustainable industrial refrigeration solutions.

In conclusion, industrial refrigerators and freezers are critical assets for a wide range of industries, playing a vital role in preserving goods, maintaining quality, and ensuring operational efficiency. Understanding the different types, key features, energy optimization strategies, and maintenance requirements is essential for making informed decisions and maximizing the value of these essential pieces of equipment. By carefully considering your specific needs and staying abreast of the latest technological advancements, you can select and maintain industrial refrigeration systems that deliver peak performance, reliability, and sustainability for years to come.