In the world of architectural and interior design, precision and efficiency are paramount. When it comes to planning commercial spaces, especially those involving food service, the placement of equipment like refrigerators is crucial. That’s where commercial refrigerator CAD blocks come into play. These digital assets are indispensable tools for designers, architects, and engineers, enabling them to visualize and integrate refrigeration units into their projects with unparalleled accuracy.

What Are Commercial Refrigerator CAD Blocks?

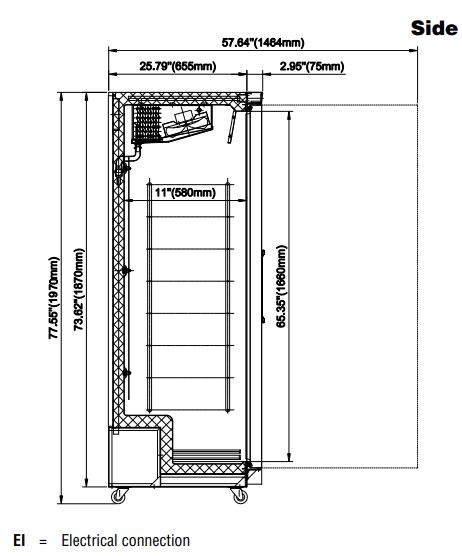

CAD blocks, short for Computer-Aided Design blocks, are pre-drawn symbols or models that can be inserted into CAD drawings. Specifically, commercial refrigerator CAD blocks represent various types of refrigeration units used in commercial settings, such as restaurants, supermarkets, and catering facilities. These blocks can include different views (top, side, front) and dimensions, allowing designers to accurately represent the equipment within their layouts.

These blocks are typically available in formats compatible with popular CAD software like AutoCAD, Revit, and SketchUp. They provide a realistic representation of the refrigerator, ensuring that the design takes into account factors like door swing, ventilation, and overall space requirements.

Why Are Commercial Refrigerator CAD Blocks Important?

Using commercial refrigerator CAD blocks offers numerous benefits:

- Accuracy: They ensure precise placement and sizing of refrigeration units, reducing the risk of errors during construction or installation.

- Efficiency: They save time by eliminating the need to draw complex equipment from scratch.

- Visualization: They provide a clear visual representation of the layout, helping clients and stakeholders understand the design.

- Coordination: They facilitate coordination between different trades, such as architects, engineers, and contractors.

- Space Planning: They assist in optimizing space utilization, ensuring that the refrigeration units fit seamlessly into the overall design.

Types of Commercial Refrigerator CAD Blocks

There are various types of commercial refrigerator CAD blocks available, catering to different needs and applications:

- Walk-in Refrigerators: Large refrigeration units designed for storing bulk quantities of food.

- Reach-in Refrigerators: Standard upright refrigerators commonly used in restaurants and cafes.

- Display Refrigerators: Refrigerated units with glass doors, designed for showcasing products.

- Undercounter Refrigerators: Compact refrigerators designed to fit under countertops.

- Blast Chillers: Refrigeration units that rapidly cool food to safe temperatures.

Where to Find Commercial Refrigerator CAD Blocks

Finding high-quality commercial refrigerator CAD blocks is essential for accurate and effective design. Here are some reliable sources:

- Manufacturer Websites: Many commercial refrigerator manufacturers provide CAD blocks of their products on their websites.

- Online Libraries: Websites like CAD Blocks Free, GrabCAD, and BIMobject offer a wide selection of free and paid CAD blocks.

- Design Software Libraries: Some CAD software programs have built-in libraries of blocks that users can access.

- Professional Design Resources: Specialized design resource websites that focus on commercial kitchen or restaurant design.

How to Use Commercial Refrigerator CAD Blocks

Using commercial refrigerator CAD blocks is relatively straightforward. Here’s a step-by-step guide:

- Download the Block: Find and download the appropriate CAD block from a reputable source.

- Import the Block: Open your CAD software and import the downloaded block.

- Position the Block: Place the block in the desired location within your drawing.

- Adjust the Block: Rotate, scale, or mirror the block as needed to fit the layout.

- Verify Dimensions: Double-check the dimensions of the block to ensure accuracy.

- Integrate into Design: Incorporate the block into the overall design, ensuring proper clearance and functionality.

Tips for Choosing the Right CAD Blocks

When selecting commercial refrigerator CAD blocks, consider the following:

- Accuracy: Ensure the dimensions and details of the block are accurate.

- Compatibility: Choose blocks that are compatible with your CAD software.

- Detail Level: Select blocks with the appropriate level of detail for your project.

- File Size: Opt for blocks with optimized file sizes to avoid slowing down your drawings.

- Source Reliability: Download blocks from reputable sources to avoid errors or malware.

The Future of CAD Blocks in Commercial Design

As technology advances, commercial refrigerator CAD blocks are becoming increasingly sophisticated. With the rise of Building Information Modeling (BIM), these blocks are evolving to include more detailed information, such as material specifications, energy efficiency ratings, and maintenance requirements. This allows for more comprehensive and integrated design processes.

Additionally, the development of parametric CAD blocks enables designers to easily customize and adapt equipment models to specific project needs, further enhancing efficiency and accuracy.

In conclusion, commercial refrigerator CAD blocks are essential tools for any design professional working on commercial spaces. By understanding their importance, types, and usage, you can streamline your design process and create accurate, efficient, and visually appealing layouts.