In today’s fast-paced world, ensuring the longevity and quality of your food has become paramount. A reliable freezer appliance is not just a convenience; it’s an essential tool for efficient meal planning, reducing food waste, and ultimately, saving you time and money. This comprehensive guide delves deep into the world of freezer appliances, exploring the diverse types available, crucial features to consider, and expert advice to help you make an informed decision that perfectly aligns with your lifestyle and requirements.

Decoding the Different Types of Freezer Appliances

The realm of freezer appliances extends far beyond a simple box that keeps things cold. Understanding the nuances of each type is the first crucial step in selecting the ideal unit for your home or business.

The Classic Chest Freezer: Maximizing Space and Efficiency

Often characterized by their horizontal, chest-like design and a top-opening lid, chest freezers are renowned for their exceptional storage capacity and energy efficiency. Their deep interior allows for the storage of bulky items and large quantities of food, making them a popular choice for families, hunters, and those who buy in bulk. The inherent design minimizes cold air loss when the lid is opened, contributing to their superior energy performance. While accessing items at the bottom might require a bit of digging, many models come with removable baskets to help organize contents effectively. Consider the available floor space, as chest freezers typically occupy a larger footprint than their upright counterparts. Their robust construction and straightforward mechanics often translate to long-term reliability, making them a wise investment for those prioritizing capacity and efficiency.

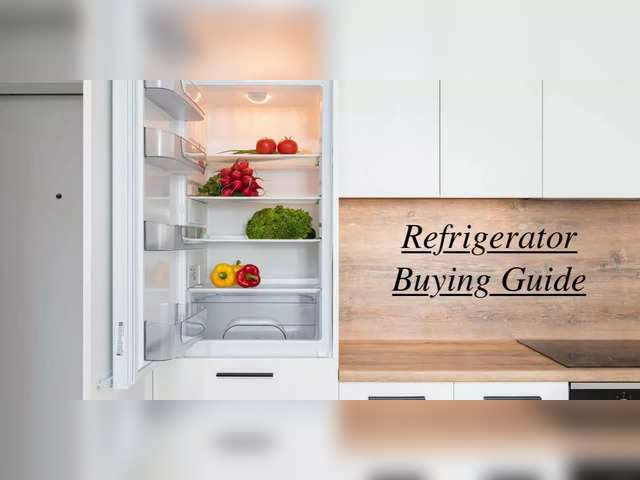

The Versatile Upright Freezer: Organization and Accessibility at Your Fingertips

Resembling a refrigerator in appearance, upright freezers offer unparalleled organization and ease of access. With shelves, drawers, and door bins, these models allow you to neatly arrange your frozen goods, making it simple to locate specific items without rummaging through layers of food. This vertical design is particularly advantageous for smaller spaces where floor area is limited. While generally less energy-efficient than chest freezers due to greater cold air loss when the door is opened, modern upright freezers often incorporate features like frost-free technology, eliminating the need for manual defrosting and maintaining optimal performance. The convenience and organizational benefits of an upright freezer make it an ideal choice for individuals and families who prioritize accessibility and efficient space utilization.

The Compact and Convenient Portable Freezer: Flexibility for On-the-Go Needs

For those who require freezing capabilities beyond the confines of their kitchen, portable freezers offer a versatile solution. These smaller, often lightweight units are designed for portability, making them perfect for camping trips, RV adventures, boats, or even as supplementary freezing space during holidays or events. They typically come with handles and can often be powered by both AC and DC sources. While their storage capacity is significantly less than that of chest or upright models, their convenience and ability to maintain freezing temperatures in various locations make them an invaluable asset for specific needs. Consider the power requirements and dimensions when selecting a portable freezer to ensure it meets your intended use.

Specialty Freezer Types: Catering to Niche Requirements

Beyond the main categories, there exists a range of specialty freezer appliances designed for specific purposes. Drawer freezers, often integrated into kitchen islands or lower cabinets, offer discreet and convenient freezing space. Wine coolers with freezing compartments provide dual functionality for wine enthusiasts. Lab and medical-grade freezers offer ultra-low temperature storage for sensitive materials. Understanding these niche options can be crucial if your needs extend beyond standard household food preservation.

Navigating the Features: What Truly Matters in a Freezer Appliance

Once you’ve determined the ideal type of freezer appliance for your needs, the next step is to consider the specific features that will enhance its functionality and efficiency.

Capacity: Matching Your Storage Needs

The internal capacity of a freezer appliance, typically measured in cubic feet, is a primary consideration. Assess your current freezing needs and anticipate future requirements. Consider the size of your household, your buying habits (bulk purchases vs. frequent smaller trips), and whether you intend to store large items like whole turkeys or sides of meat. Overestimating can lead to wasted energy cooling empty space, while underestimating will result in insufficient storage. Carefully evaluate your long-term freezing goals to select a freezer appliance with the appropriate capacity.

Energy Efficiency: Saving Money and the Planet

A freezer appliance operates continuously, making energy efficiency a critical factor in long-term cost savings and environmental impact. Look for models with high Energy Star ratings, indicating superior energy performance. Features like thicker insulation, advanced compressors, and smart defrost cycles contribute to greater efficiency. While the initial purchase price of an energy-efficient model might be slightly higher, the long-term savings on your electricity bill will more than compensate for the difference. Pay close attention to the estimated annual energy consumption listed on the appliance’s energy guide.

Defrost Type: Frost-Free Convenience vs. Manual Efficiency

Frost-free freezers utilize automatic defrost cycles to prevent the buildup of ice, eliminating the need for manual defrosting. This offers significant convenience and ensures optimal energy efficiency by preventing ice buildup, which can hinder performance. However, some argue that the defrost cycles can slightly dry out food over extended periods. Manual defrost freezers, on the other hand, require periodic manual defrosting to remove accumulated ice. While this involves some effort, they are generally more energy-efficient and can maintain a more consistent temperature. Weigh the convenience of frost-free operation against the potential energy savings and food preservation characteristics of a manual defrost model.

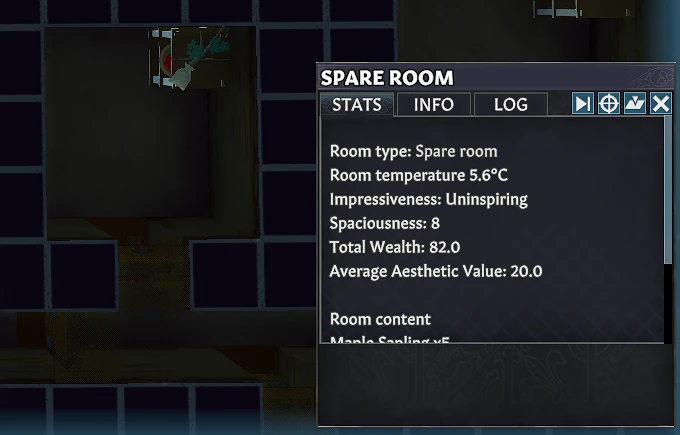

Temperature Control: Precision for Optimal Preservation

Reliable and accurate temperature control is essential for maintaining the quality and safety of your frozen food. Look for freezer appliances with adjustable temperature settings and clear temperature displays. Some advanced models offer precise digital temperature control, allowing you to fine-tune the internal environment to suit specific types of food. Consistent temperature maintenance is crucial for preventing freezer burn and ensuring long-term preservation.

Organization Features: Maximizing Usability

The internal organization of a freezer appliance significantly impacts its usability. Consider the number and type of shelves, drawers, and door bins. Adjustable shelves offer flexibility in accommodating items of various sizes. Pull-out drawers provide easy access to frequently used items. Baskets in chest freezers help to compartmentalize storage and prevent smaller items from getting lost at the bottom. Evaluate your typical frozen food inventory and choose a model with an organizational layout that suits your needs.

Security Features: Protecting Your Investment

For some users, particularly those with young children or in shared living spaces, a locking mechanism on the freezer appliance can be a valuable security feature. This prevents unauthorized access and accidental temperature adjustments, ensuring the safety and integrity of your stored food.

Noise Level: Maintaining a Peaceful Environment

While freezer appliances are generally not excessively noisy, the operational hum can be a consideration, especially if the unit is located in a living area or near bedrooms. Check the manufacturer’s specifications for noise levels (measured in decibels) if quiet operation is a priority.

Smart Features: Connectivity and Convenience

Increasingly, freezer appliances are incorporating smart features such as Wi-Fi connectivity, remote temperature monitoring, and alerts for door ajar or temperature fluctuations. These features can provide added convenience and peace of mind, allowing you to manage your freezer remotely and receive notifications about potential issues.

Expert Insights: Making the Right Freezer Appliance Choice

Selecting the perfect freezer appliance involves more than just considering the features. Here are some expert tips to guide your decision-making process:

- Measure Your Space: Before you even begin browsing, accurately measure the available space where you intend to place the freezer. Consider door swing and ventilation requirements as specified by the manufacturer.

- Consider Your Budget: Freezer appliances range in price depending on size, features, and brand. Determine your budget beforehand and focus on models that offer the best value within your price range. Remember to factor in long-term energy costs.

- Read Reviews: Research different models and read customer reviews to gain insights into real-world performance, reliability, and any potential issues.

- Check the Warranty: A good warranty provides peace of mind and protects your investment against manufacturing defects. Compare the warranty terms offered by different manufacturers.

- Think Long-Term: A freezer appliance is a significant investment that should last for many years. Consider your future needs and choose a model that can accommodate potential changes in your lifestyle or family size.

- Visit a Showroom: If possible, visit a local appliance showroom to see different models in person and get a better feel for their size, features, and build quality.

- Inquire About Delivery and Installation: Check with the retailer about delivery and installation services, especially for larger models.

Investing in Preservation: Securing Your Food’s Future with the Right Freezer Appliance

Choosing the right freezer appliance is an investment in food preservation, convenience, and long-term savings. By carefully considering the different types available, evaluating key features, and following our expert tips, you can confidently select a model that perfectly aligns with your individual needs and lifestyle. Whether you prioritize maximum storage capacity, organizational efficiency, or portable convenience, the ideal freezer appliance is out there, ready to unlock the power of preservation for your household or business. Embrace the benefits of efficient food storage and enjoy the peace of mind that comes with knowing your food is safely and effectively preserved for the future.

© 2025 All Rights Reserved – Your Expert Appliance Guide